The Art and Industry of Sand Casting in China

Sand casting is one of the oldest and most versatile metal forming processes, widely used in various industries, including automotive, aerospace, and manufacturing. In China, the practice of sand casting has flourished, combining traditional techniques with modern technology to meet the increasing demands of both domestic and international markets. This article explores the significance, methods, and advancements in sand casting in China, highlighting how the country has become a global leader in this field.

Historical Context

The roots of sand casting can be traced back thousands of years, with evidence of its use in ancient China to create intricate metal artifacts. Over the centuries, this time-honored method evolved, adapting to the changing needs of society. The resurgence of industrialization in the late 20th century catalyzed advancements in casting technology, making China a powerhouse in manufacturing and metalworking.

The Sand Casting Process

The sand casting process involves several key steps. First, a pattern, usually made of metal or plastic, is created to form the desired shape of the final product. This pattern is then placed in a mold made of a mixture of sand, clay, and water, which provides the necessary strength and durability. Once the mold is prepared, molten metal is poured into it. After cooling, the mold is broken apart to reveal the cast object. The entire process can be adapted for precision and complexity, accommodating a wide range of metal types—including aluminum, iron, and copper alloys.

China's vast network of foundries has perfected this technique, enabling the production of everything from small components to large machine parts. The flexibility and cost-effectiveness of sand casting make it an attractive option for manufacturers.

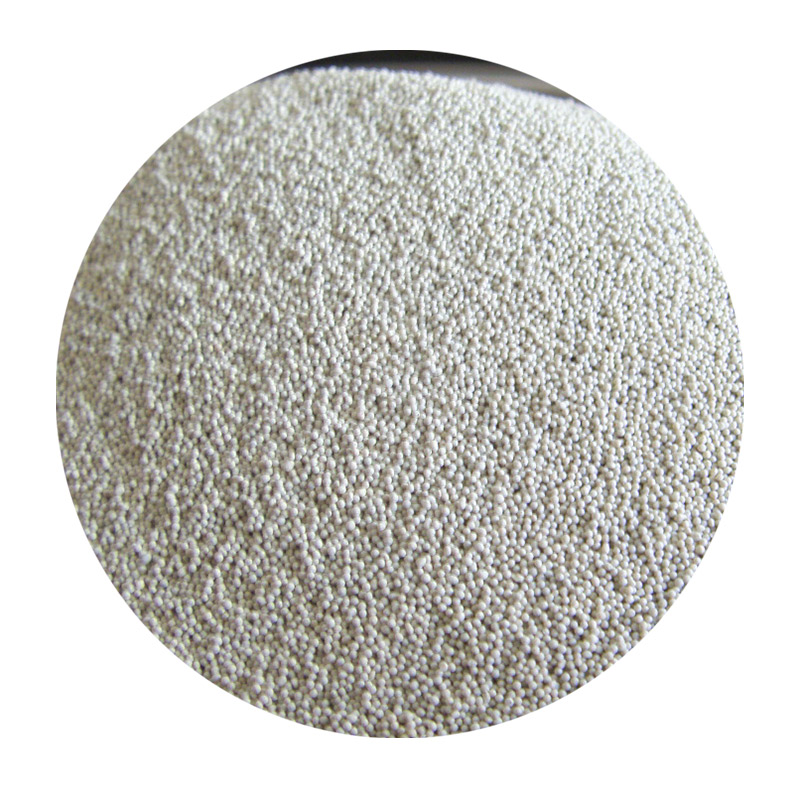

china sand casting

Advantages of Sand Casting in China

One of the primary advantages of sand casting in China is its scalability. Chinese manufacturers can produce both small batches and large volumes of cast parts, meeting the needs of various sectors. Furthermore, the availability of high-quality materials and skilled labor contributes to the competitive edge of Chinese sand casting products.

Additionally, China’s investment in research and development has led to enhanced techniques and technologies. Innovations such as 3D printing for pattern making and the use of advanced simulation software have optimized the casting process, ensuring better quality control and reducing material waste.

Environmental Considerations

As the world increasingly focuses on sustainable practices, the sand casting industry in China is also transitioning towards more eco-friendly operations. Manufacturers are exploring ways to recycle sand and reduce energy consumption during the casting process. Efforts to implement cleaner technologies and adhere to stricter environmental regulations demonstrate the industry's commitment to sustainable development.

Conclusion

In conclusion, sand casting remains a vital part of China's manufacturing landscape. With its rich history, adaptability, and ongoing innovations, the country continues to solidify its position as a leader in the global sand casting industry. As technology evolves and environmental challenges grow, China's foundries are likely to adapt, ensuring that this ancient art continues to thrive in the modern world. Through a combination of traditional craftsmanship and cutting-edge practices, China is poised to influence the future of sand casting for many years to come.

Post time:វិច្ឆិកា . 02, 2024 09:17

Next:golden sands concrete