3D Sand Printing Process Revolutionizing Manufacturing

The 3D sand printing process represents a groundbreaking advancement in the field of additive manufacturing, allowing for the creation of complex sand molds and cores with unparalleled precision and efficiency. This innovative method utilizes precise layers of sand to construct intricate patterns that are critical in a variety of industries, particularly in casting operations.

3D Sand Printing Process Revolutionizing Manufacturing

One of the significant advantages of the 3D sand printing process is its ability to reduce material waste significantly. Traditional sand casting often involves extensive machining of the molds, leading to considerable scrap material. In contrast, 3D sand printing only uses the material necessary for the mold itself, minimizing waste and lowering costs. Furthermore, it allows for the quick production of complex geometries that would be challenging, if not impossible, to achieve through conventional methods.

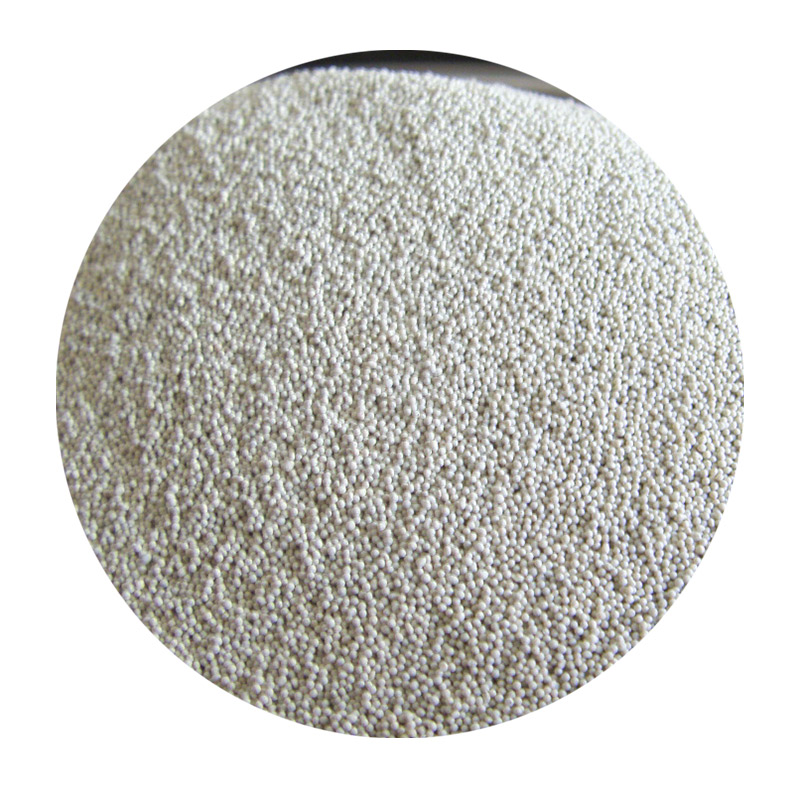

3d sand printing process

The versatility of 3D sand printing is highlighted by its application in various industries, including automotive, aerospace, and art. For instance, manufacturers can produce lightweight components with intricate designs, which can enhance the performance and aesthetics of products. Additionally, artists and sculptors are embracing this technology to create fine art pieces, leveraging its potential for creativity and precision.

The rapid prototyping capabilities of 3D sand printing also serve to significantly reduce lead times in manufacturing. Instead of waiting weeks for a traditional mold to be produced, manufacturers can now generate functional prototypes in mere days. This acceleration not only enhances productivity but also allows for more iterative testing and modeling, ultimately leading to better-quality products.

Moreover, as industries increasingly prioritize sustainability, 3D sand printing aligns with these goals by utilizing environmentally friendly materials and reducing energy consumption. The technology's ability to print parts on demand diminishes the need for large inventories, thereby further contributing to sustainable manufacturing practices.

In conclusion, the 3D sand printing process is revolutionizing the way molds and cores are produced across multiple sectors. Its efficiency, cost-effectiveness, and ability to create complex shapes make it an indispensable tool for modern manufacturing. As technology continues to advance, we can expect even more innovative applications and improvements in the 3D sand printing landscape, solidifying its place in the future of manufacturing.

Post time:តុលា . 09, 2024 06:52

Next:resin with sand