The Art of Sanding in 3D Printing Achieving Surface Perfection

The world of 3D printing has revolutionized manufacturing and prototyping, offering creativity and customization at our fingertips. However, one challenge that often arises in the 3D printing process is achieving a smooth surface finish. While printers can produce intricate designs, the layers that build up during printing can leave behind a rough texture. This is where sanding comes into play—a crucial step in the post-processing phase that not only enhances aesthetics but also improves functionality.

Understanding the Importance of Sanding

Sanding serves multiple purposes in the realm of 3D printing. Primarily, it helps to remove visible layer lines, which can distract from the overall appearance of the printed object. A smooth surface is essential, especially for parts that need to fit together seamlessly or for artistic projects where visual appeal is paramount. Moreover, sanding can help remove any supports or artifacts left from the printing process, resulting in a cleaner finish.

Additionally, sanding can improve the adhesion between layers in parts that may undergo further processing, such as painting or sealing. A smoother surface ensures better paint adherence and a more professional-looking end product. Ultimately, sanding is not just about aesthetics; it's about elevating the quality of the printed object.

Choosing the Right Tools

The tools and materials you choose for sanding are vital to achieving the desired finish. Sandpaper is the most common choice, available in various grits. Starting with a lower grit (around 100-200) can help remove larger imperfections and layer lines. Progressing to finer grits (up to 2000 or higher) allows for a smoother finish.

Alternatively, sanding sponges and electric sanders can also be effective, especially for larger or flat surfaces. Some enthusiasts even turn to specialized tools like rotary sanders to speed up the process, particularly for more robust materials. Regardless of the tools used, it’s essential to approach the task with patience, gradually working through the grits to prevent damaging the print.

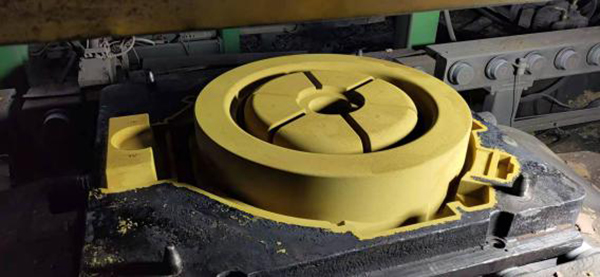

3d print sanding

Techniques for Effective Sanding

To achieve the best results, a few techniques are worth considering. First, ensure that the printed object is clean and free of dust or debris before beginning sanding. This prevents any unwanted scratches or imperfections from being added to the surface.

A common technique is to use circular motions while sanding, which can help to evenly distribute pressure and avoid creating flat spots. It's also advisable to frequently check progress by wiping the surface clean, allowing you to see how smooth it has become. For complex geometries or detailed sections, using a smaller piece of sandpaper can provide better control and precision.

Another method is wet sanding, which involves using water to lubricate the sandpaper. This not only helps to reduce dust but also minimizes the chances of scratching the surface. Wet sanding can produce incredible results, especially with finer grits, and is recommended for achieving a glass-like finish.

Final Touches

After sanding, applying a filler primer or paint can enhance the surface even further. Primers not only provide a uniform base for painting but can also fill in any remaining minor imperfections. Once dry, fine sanding of the primer can lead to an exceptionally smooth and professional finish.

In conclusion, while 3D printing opens doors to innovation and creativity, sanding remains a vital part of bringing those creations to life. By investing the time and effort into the sanding process, you can transform a rough print into a polished masterpiece. Armed with the right tools, techniques, and a bit of patience, the journey to surface perfection is well within reach. Happy sanding!

Post time:តុលា . 17, 2024 05:03

Next:resin coated sand manufacturing process