Advanced Techniques for Professional Results For those seeking truly professional results, consider integrating advanced techniques such as filler application or priming. Applying a filler primer after the initial sanding stages can fill minor imperfections, and help you achieve a flawless surface after subsequent coats and sanding. Spray primers tailored for plastic surfaces offer an even application, bridging the microscopic gaps that standard sanding might miss. Leveraging Expert Insights and Community Resources Engaging with the 3D printing community can be an invaluable resource. Many experts share insights and innovative techniques through forums, online workshops, and video tutorials. Participating in these communities not only expands your skill set but also provides first-hand experience from other professionals who have faced similar challenges. The Road to Mastery While the process might seem labor-intensive, with dedication and the right techniques, sanding can transform your 3D printed models from ordinary objects into masterpieces. This is where the art intersects with engineering, and where expertise makes all the difference. Building Trust Through Quality Assurance The journey doesn't end once you achieve a perfectly sanded piece. Ensuring consistent quality across multiple prints builds trust with end-users who rely on your products. Implementing quality control measures, such as visual inspections and quality tests for surface uniformity, ensures that each product meets the highest possible standards. In summary, mastering 3D printed sanding is a vital skill for anyone committed to delivering top-tier products. By understanding the nuances of different materials, investing in the right tools, adhering to safety protocols, and continually learning from expert resources, you can achieve exceptional quality that stands out in today's competitive market. Post time:កុម្ភៈ . 08, 2025 06:48

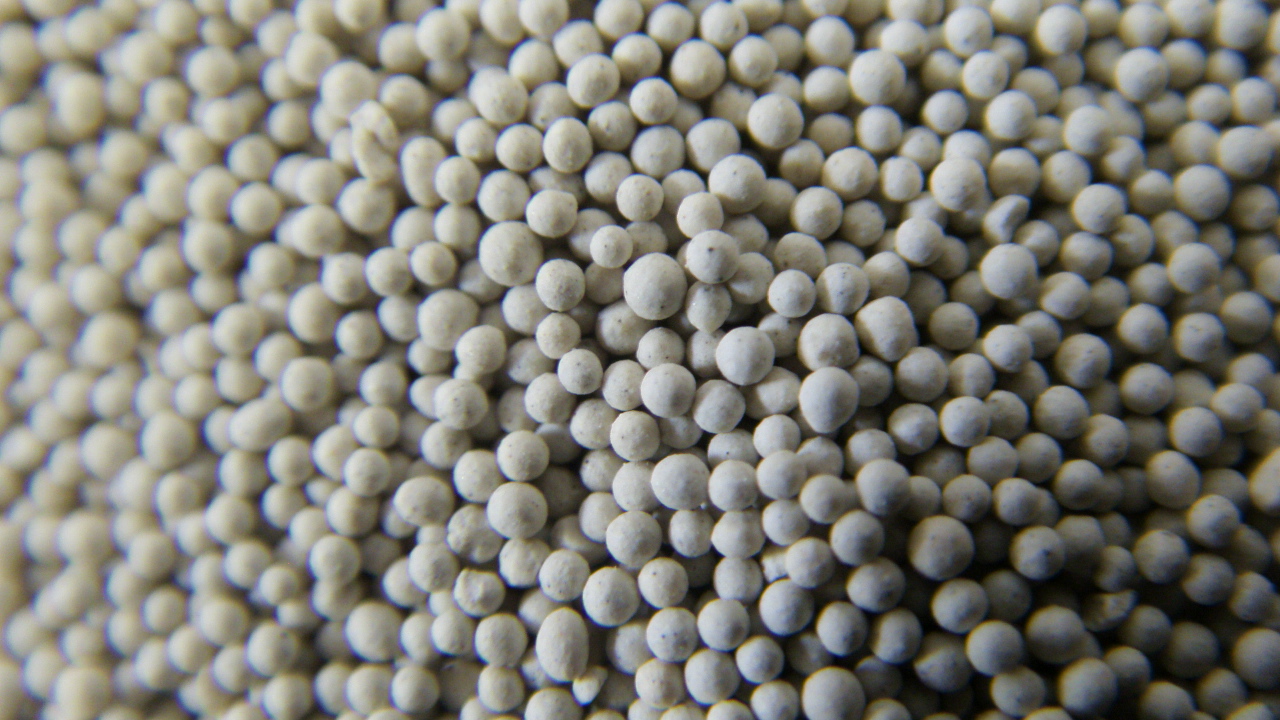

Next:Ceramic casting sand for sand 3d printing