Understanding Sintering Sand A Key Component in Metal Casting

Sintering sand, commonly used in the metal casting process, is a specialized type of sand that plays a crucial role in creating intricate metal parts. This material undergoes a unique process that transforms the quality of sand, making it a vital element in many industrial applications, particularly in the manufacturing of complex components.

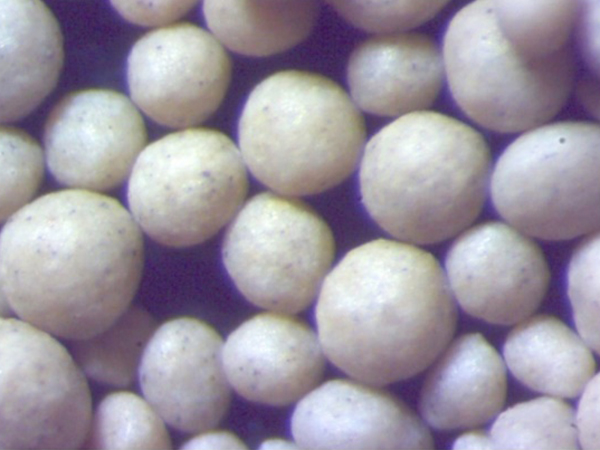

The process of sintering involves the application of heat to a material in a solid state, encouraging particles to bond without melting. In the context of sintering sand, this process allows the sand particles to fuse together, providing a stable mold structure that can withstand the high temperatures of molten metal. This characteristic is essential for ensuring that the final cast product accurately reflects the desired specifications and maintains structural integrity.

One of the primary advantages of using sintering sand in metal casting is its ability to create highly detailed and precise molds. The fine particle size and uniformity of sintering sand allow for the production of molds with intricate designs, which is especially important in industries such as automotive, aerospace, and electronics. These industries often require components with tight tolerances and complex geometries, and sintering sand provides the necessary precision.

sintering sand

Moreover, sintering sand is highly versatile and can be mixed with various additives to enhance its properties. For example, binders can be introduced to improve the strength of the mold and increase its durability against the stresses of the casting process. Additionally, different grades of sand can be selected based on the specific requirements of the casting application, allowing for customization that can significantly affect the quality of the final product.

Sustainability is another aspect worth mentioning in the context of sintering sand. The recycling of sand used in metal casting processes is becoming increasingly common. After a casting is complete, the sand can often be reclaimed, processed, and reused in new mold applications, minimizing waste and reducing costs. This not only contributes to more sustainable manufacturing practices but also helps industries meet their environmental responsibilities.

In conclusion, sintering sand is an essential component in the field of metal casting. Its unique properties and advantages make it ideal for producing detailed and high-quality molds, which are pivotal in creating complex metal parts. With advancements in technology and a growing emphasis on sustainability, the use of sintering sand will likely continue to evolve, enhancing its importance in various manufacturing sectors. As industries seek to meet the challenges of modern production, sintering sand stands out as a reliable material that supports innovation and efficiency in casting practices.

Post time:Қар . 20, 2024 11:41

Next:sanding casting resin