The Versatility and Importance of Sanded Resin in Modern Manufacturing

The advancement of industrial materials has led to the rise of innovative substances that greatly enhance the efficiency and quality of manufacturing processes. One such notable material is sanded resin, a composite that is increasingly gaining traction in various applications. With its unique properties, sanded resin is revolutionizing sectors ranging from furniture production to construction and even automotive industries.

Sanded resin is essentially a synthetic polymer that undergoes a thorough sanding process to achieve a smooth surface finish. This treatment not only optimizes its aesthetic appeal but also enhances its functionality. The fine texture created through sanding allows for better adhesion in coatings and finishes, making it an ideal choice for products that require a sleek, polished appearance.

One of the prime advantages of sanded resin is its durability. Unlike traditional wood or plaster materials that can warp, chip, or degrade over time, sanded resin boasts excellent resistance to moisture, heat, and UV radiation. This resilience makes it an ideal material for outdoor furniture or any application exposed to varying weather conditions. Moreover, the longevity of sanded resin products translates to reduced maintenance and replacement costs, offering significant savings for consumers and manufacturers alike.

In the furniture industry, sanded resin is often utilized in the production of cabinetry, countertops, and decorative features. Its versatility allows for intricate designs while retaining structural integrity. As designers strive for unique, modern aesthetics, sanded resin offers a canvas that can be molded into various shapes and colors, pushing the boundaries of conventional furniture design.

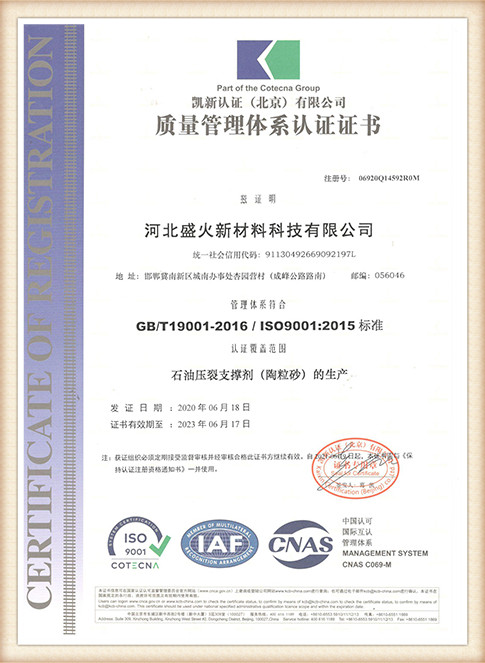

sanded resin

In the realm of construction, sanded resin is gaining popularity as an alternative to traditional building materials. Its lightweight nature paired with robust strength makes it suitable for various applications, including wall paneling, flooring, and even roofing. Additionally, sanded resin can be easily customized to meet the specific needs of a project, allowing builders to achieve their desired outcomes without compromising durability.

The automotive industry is also exploring the benefits of sanded resin in the production of components such as dashboards, interior trims, and even external parts. With the push for lighter and more fuel-efficient vehicles, the combination of sanded resin's lightweight properties and its strength is proving to be a game-changer. It enables manufacturers to reduce the overall weight of vehicles while maintaining safety and performance standards.

Furthermore, the environmental aspect of sanded resin cannot be overlooked. Many modern sanded resins are developed using sustainable practices or recycled materials, aligning with the growing demand for eco-friendly options in manufacturing. As consumers become increasingly aware of their environmental footprint, the shift towards using environmentally responsible materials is becoming a critical consideration for businesses.

In conclusion, sanded resin presents a myriad of advantages that make it a valuable asset in various industries. Its durability, aesthetic versatility, and potential for customization enable manufacturers to create innovative and functional products that meet the ever-evolving demands of consumers. As technology continues to advance, we can expect sanded resin to play an integral role in shaping the future of manufacturing, paving the way for sustainable and high-performance materials that redefine industry standards. As we embrace these modern solutions, the impact of sanded resin will be felt across multiple sectors, ultimately enhancing both product quality and consumer satisfaction.

Post time:ოქტ . 12, 2024 13:29

Next:sand casting foundry