Understanding Foundry Sand Specifications

Foundry sand is a critical component in the casting process, providing the necessary properties to create high-quality metal castings. The specifications of foundry sand dictate its suitability for various applications in foundries, influencing the characteristics of the finished product. To ensure optimal performance and consistency, it is crucial to understand the key specifications that govern the use of foundry sand.

Composition of Foundry Sand

Foundry sand is primarily composed of silica (SiO2), which makes up about 90-95% of the total composition. This high silica content provides excellent thermal stability, allowing the sand to withstand the high temperatures encountered during the casting process. In addition to silica, other materials such as clay, silt, and various additives are often mixed to enhance the sand's properties. For example, clay improves the binding characteristics of the sand, contributing to the sand mold's strength and integrity.

Grain Size Distribution

One of the most critical specifications of foundry sand is its grain size distribution. The effectiveness of sand in mold-making largely depends on the size and shape of its grains. The ideal grain size should promote good moldability while ensuring adequate airflow during casting. Typically, foundry sands are graded according to the U.S. Standard Sieve Series, with preferred grain sizes ranging from 0.1 mm to 0.5 mm. A well-graded sand mix that includes various grain sizes enhances the mold’s compactness and reduces the likelihood of defects such as holes or tears in the final casting.

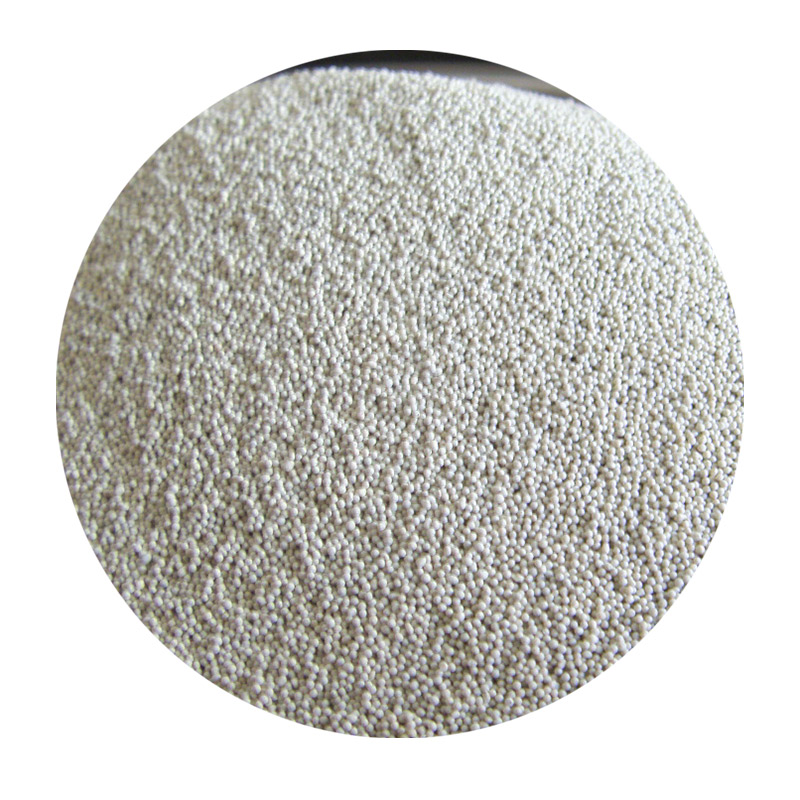

Grain Shape and Surface Texture

The shape of sand grains significantly influences the performance of foundry sand. Round grains are generally favored because they provide better flowability and mold filling properties. This shape also leads to improved strength in the mold due to better packing. Conversely, angular grains, while potentially offering greater friction and mold strength, can cause difficulties in achieving the desired mold density. Furthermore, the surface texture of the grains affects their bonding capabilities. Smooth particles tend to bond better than rough ones, making it essential to consider these factors when selecting foundry sand.

foundry sand specifications

Moisture Content

Moisture content is another essential specification for foundry sand, as it affects the sand's plasticity and workability. A typical moisture content for green sand (a common type of foundry sand) ranges from 2% to 6%. Too much moisture can lead to defects such as steam explosions during the casting process, while too little can result in insufficient mold strength or cracks. Therefore, maintaining the appropriate moisture range is crucial for achieving the desired molding characteristics and final casting quality.

Permeability

Permeability refers to the ability of the sand mold to allow gases to escape during the pouring of molten metal. Adequate permeability prevents gas-related defects in the casting, such as blisters or holes. Foundry sands with good permeability typically have lower clay content and a well-graded grain size distribution. It is essential to balance permeability with other properties like strength to ensure a successful casting process.

Testing and Quality Control

Regular testing and quality control measures are vital for maintaining sand specifications within the desired range. Tests for grain size, moisture content, clay percentage, and permeability should be conducted frequently to ensure consistency. Adjustments may be necessary based on the test results to maintain optimal performance in the foundry.

Conclusion

In summary, foundry sand specifications encompass various physical and chemical properties that significantly impact the casting process. Understanding the composition, grain size distribution, shape, moisture content, and permeability of foundry sand is essential for achieving high-quality metal castings. By adhering to these specifications and implementing rigorous quality control measures, foundries can ensure the production of defect-free castings while enhancing efficiency and reducing costs. With the right knowledge and application of foundry sand specifications, the industry can continue to innovate and improve casting practices, leading to better products and processes.

Post time:ოქტ . 02, 2024 06:28

Next:Innovative Methods for Sustainable Foundry Sand Recycling and Reuse in Metal Casting Industry