The Importance of Ceramic Sanding Discs in Modern Abrasive Techniques

Ceramic sanding discs have emerged as a vital tool in the world of abrasives, revolutionizing the way surface finishing and material removal are approached in various industries. These discs, known for their durability and efficiency, are integral in applications ranging from woodworking to metalworking and automotive refinishing.

One of the standout features of ceramic sanding discs is their exceptional hardness. Manufactured from advanced ceramic materials, these discs can withstand high heat and resist wear much better than traditional sanding discs. This property is particularly beneficial when working with tough materials such as stainless steel or hardened alloys, where conventional abrasive materials may quickly degrade.

Another significant advantage of ceramic sanding discs is their aggressive cutting ability. Unlike sandpaper, which can become clogged and lose effectiveness quickly, ceramic discs maintain their cutting performance over time. This results in faster material removal rates, allowing for increased productivity. In many cases, users find that they can accomplish the same tasks in a fraction of the time compared to using other abrasive types.

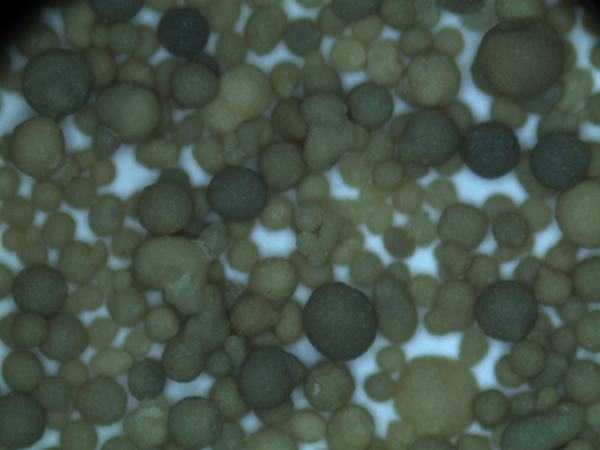

ceramic sanding discs

Ceramic sanding discs also feature a unique grain structure that enhances their performance. The self-sharpening nature of the ceramic grains means that as the disc is used, new, sharp edges are constantly exposed. This self-sharpening property not only prolongs the life of the disc but also ensures that users achieve a consistent finish throughout the sanding process. This is particularly important in applications where surface integrity and finish quality are paramount.

Furthermore, these sanding discs are available in a variety of grits, making them versatile tools for different surface preparation tasks. Whether it's rough grinding or fine finishing, ceramic sanding discs can cater to a wide range of applications. This versatility means that users can rely on a single type of disc for multiple tasks, streamlining their workflow and reducing costs.

In addition to their practical benefits, ceramic sanding discs contribute to overall workplace safety. The durability of the discs means that there is less risk of breakage during operation, reducing the chances of accidents that can result from flying debris.

In conclusion, ceramic sanding discs represent a significant advancement in abrasive technology. Their combination of durability, cutting efficiency, and versatility makes them an indispensable tool for professionals across various industries. As technology continues to advance, we can expect these discs to play an even more prominent role in the future of material working and finishing techniques.

Post time:სექ . 13, 2024 17:54

Next:Golden Sands Development - Sviluppo Sostenibile e Innovativo