Sand Casting The Essential Role of Sand in Metal Casting

Sand casting, a widely used manufacturing process, plays a vital role in the production of metal components across various industries. This method involves creating a mold from a mixture of sand, clay, and water, into which molten metal is poured to form intricate shapes and designs. While several materials can serve as molds in the casting process, sand remains the most popular choice due to its unique properties and numerous advantages.

Characteristics of Sand for Casting

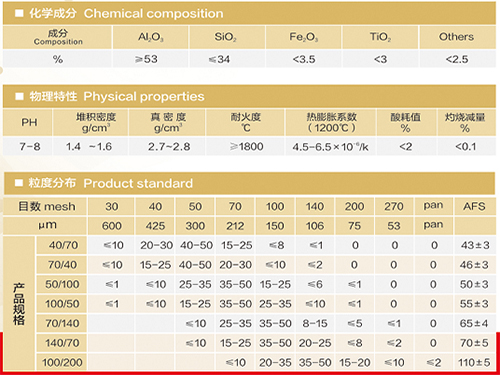

The type of sand most commonly used in metal casting is silica sand, known for its high-temperature resistance and ability to withstand the intense heat generated during the metal pour. A key feature of casting sand is its grain size, which can vary to create different levels of finish and detail in the final product. Coarser sand allows for better airflow and easier removal of the casting after it has cooled, while finer sand can produce smoother surfaces, which can reduce the need for additional finishing processes.

In addition to grain size, the composition of the sand mixture can significantly affect the casting process. Sand is often mixed with a bonding agent, typically clay, which helps the sand grains stick together, forming a more stable mold. Water is added to the mixture to activate the bonding agent and ensure that the sand retains its shape. The right proportions of these components are crucial, as they determine the mold's ability to hold its form under the weight of molten metal and during the cooling process.

Advantages of Sand Casting

One of the most significant advantages of sand casting is its versatility. It can accommodate a wide range of metal types, including aluminum, brass, and iron, making it suitable for producing everything from small components to large engine blocks. Moreover, the method allows for the creation of complex shapes that would be challenging or impossible to achieve with other manufacturing techniques.

sand for metal casting

Cost-effectiveness is another critical factor in the popularity of sand casting. The materials involved—primarily sand and clay—are relatively inexpensive compared to other casting methods like investment casting, which uses more costly materials and processes. Additionally, sand molds can be reused multiple times, further reducing production costs. However, the durability of molds can vary, with some requiring replacement after a limited number of uses, a characteristic that manufacturers must keep in mind when planning production.

Environmental Considerations

The sand casting process is relatively environmentally friendly compared to some other manufacturing methods. Sand itself is an abundant resource and can often be reclaimed and reused from prior castings, minimizing waste. Similarly, advancements in industrial practices have led to processes that reduce emissions and other environmental impacts associated with metal casting.

However, challenges remain, particularly concerning the disposal of spent sand and other materials used in the casting process. The industry continually seeks to enhance sustainability through innovative solutions, such as developing biodegradable binders and recycling systems to reclaim and repurpose materials rather than sending them to landfills.

Conclusion

In conclusion, sand casting remains a cornerstone of metal manufacturing due to its unique properties, versatility, and cost-effectiveness. The careful selection and preparation of sand are critical for producing high-quality castings that meet the stringent demands of various industries. As technology advances, the sand casting process continues to evolve, incorporating more sustainable practices and improving efficiency. The enduring importance of sand in metal casting ensures that it will remain a vital part of manufacturing processes for years to come.

Post time:12月 . 29, 2024 08:58

Next:cerabead