Understanding Sand for Casting The Backbone of Metal Foundry

Sand casting, one of the oldest and most versatile metalworking processes, relies heavily on the properties and characteristics of sand used in the casting process. The choice of sand can significantly affect the quality, finish, and dimensional accuracy of the final metal product. This article explores the composition, types, properties, and applications of sand in casting, providing a comprehensive understanding of its significance in the foundry industry.

Composition of Sand for Casting

The primary material used in sand casting is silica (silicon dioxide, SiO2), which can be found in various forms such as quartz. Silica sand is favored due to its high melting point, resistance to thermal deformation, and availability. Other materials, such as olivine, zircon, and chromite, can also be used, depending on the specific requirements of the casting process and the type of metal being poured.

Additives play a crucial role in enhancing the properties of sand. Clay, for example, is often used as a binder to improve the strength and cohesiveness of the sand mixture. Bentonite clay is particularly popular for this purpose. Water is added to the mixture to activate the clay and achieve the desired consistency. Additionally, other materials such as coal dust may be incorporated to improve the surface finish of the cast product.

Types of Sand Used in Casting

There are several types of sand commonly employed in casting processes, each with its unique properties and advantages

1. Green Sand This is a mixture of sand, clay, and water, typically used in foundries for ferrous and non-ferrous metals. Green sand is easy to mold and offers good permeability, allowing gases to escape during the pouring of molten metal.

2. Dry Sand This is sand that has been dried to remove moisture before being used in the casting process. Dry sand molds are more rigid than green sand molds and are often used for larger or more complex castings.

3. Resin-Bonded Sand This type involves mixing sand with a resin binder that hardens when heat is applied. This method allows for greater detail and precision in the castings, making it suitable for high-quality applications, though it can be more expensive than traditional methods.

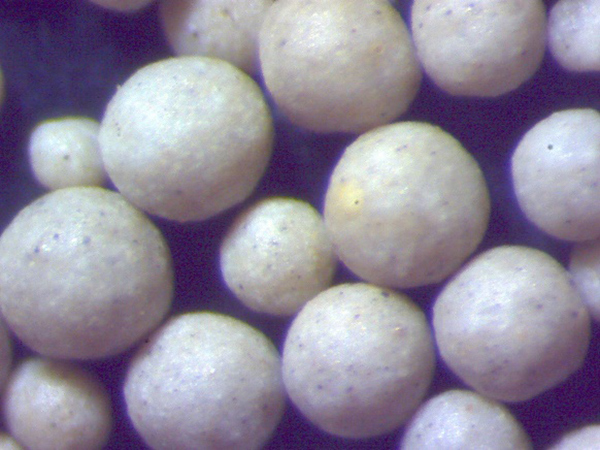

sand for casting

4. Synthetic Sand Made from processed materials, synthetic sand may have controlled properties that enhance performance, such as improved thermal stability or reduced impurities. These sands can be tailored to meet specific casting requirements.

Properties of Sand for Casting

The effectiveness of sand in casting is determined by several key properties

- Grain Size The size and distribution of sand grains affect the mold's strength and the surface finish of the casting. Finer grains typically result in smoother surfaces, while coarser grains provide better strength and firmness.

- Permeability This refers to the ability of the sand mold to allow gases to escape during the pouring of molten metal. High permeability is essential to prevent gas entrapment, which can result in defects and poor quality in the final casting.

- Thermal Stability The sand must withstand the high temperatures of molten metal without breaking down or deforming. This property is crucial for maintaining mold integrity during the casting process.

- Plasticity The ability of the sand to retain its shape when compacted is vital for creating detailed and complex shapes in molds. Plasticity is influenced by the type and amount of binder used.

Applications of Sand Casting

Sand casting is widely used across various industries, including automotive, aerospace, and construction. Its ability to produce intricate shapes and parts with relatively low costs makes it an attractive option for manufacturers. Common applications include engine blocks, turbine housings, and decorative items.

In conclusion, sand is an indispensable material in the casting industry, with its composition, type, and properties directly influencing the quality and efficiency of the casting process. Understanding the intricacies of sand for casting not only enhances production capabilities but also ensures that manufacturers can produce high-quality metal components that meet industry standards and customer expectations. As technology advances, the development of improved sand materials and binding agents will undoubtedly continue to shape the future of sand casting.

Post time:des . 12, 2024 09:35

Next:how to sand a 3d print