Understanding the Role of Sand in Casting Processes

Sand casting, one of the oldest and most widely used metal casting techniques, relies heavily on the properties and composition of sand to produce high-quality metal parts. This process involves creating a mold from sand that shapes molten metal into desired forms. While various materials can be used for casting, sand remains a favored choice due to its unique characteristics.

The primary type of sand used in sand casting is silica sand, which is composed mainly of quartz. Its high melting point makes it suitable for withstanding the extreme temperatures of molten metal, which can exceed 1,600 degrees Celsius. Additionally, silica sand has excellent thermal conductivity properties, allowing it to dissipate heat rapidly. This feature is critical, as it helps in minimizing defects that may arise from uneven cooling rates, such as warping or cracking.

One of the key advantages of using sand in casting is its ability to be reused. After a casting is complete, the sand can be reclaimed, cleaned, and mixed with fresh sand for subsequent castings. This not only leads to cost-effective production but also promotes environmental sustainability by reducing waste.

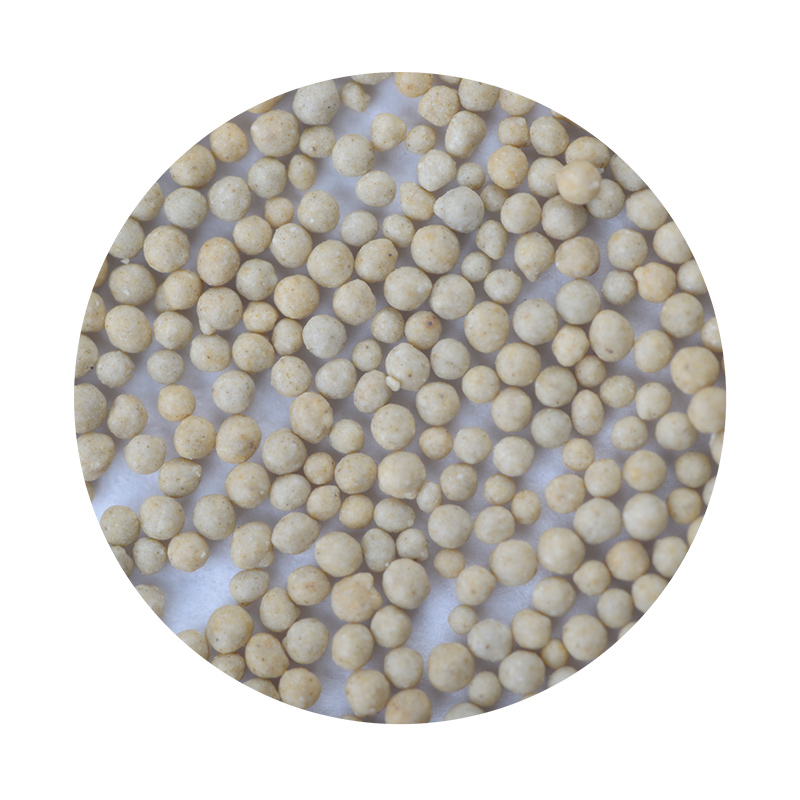

sand in cast

Moreover, the binding agents added to the sand mixture play a significant role in affecting the final quality of the casted product. Clay, for instance, is often used to improve the sand's cohesiveness, allowing it to hold shape better during the molding process. Other materials, such as water and chemical binders, can be mixed with sand to enhance its properties and achieve the required mold strength.

Another important aspect to consider is the grain size and distribution of the sand. Finer grains provide better surface finish for the finished product but may drain the molten metal slower, leading to potential defects. Conversely, coarser sand allows for quicker pouring but may result in a rougher finish. Striking a balance between these factors is crucial for achieving the desired outcome.

In summary, sand plays a pivotal role in the casting process, affecting everything from mold strength to surface finish. Its unique properties, combined with the ability to be recycled, make it an ideal material for the production of intricate metal parts. As technology advances, techniques will continue to evolve, but the fundamental importance of sand in casting will likely endure, ensuring that it remains a cornerstone of the manufacturing industry for years to come.

Post time:Սպտ . 22, 2024 11:29

Next:sand casting suppliers