Understanding China’s Sand Casting Industry

China has emerged as a global leader in the manufacturing sector, particularly in the field of sand casting. Sand casting, also known as sand mold casting, is one of the oldest and most versatile manufacturing processes, allowing for the production of metal parts with complex geometries. The process involves creating a mold from sand and then pouring molten metal into the mold to produce the desired shape. This article explores the dynamics of sand casting factories in China, their technological advancements, and their impact on the global market.

The Process of Sand Casting

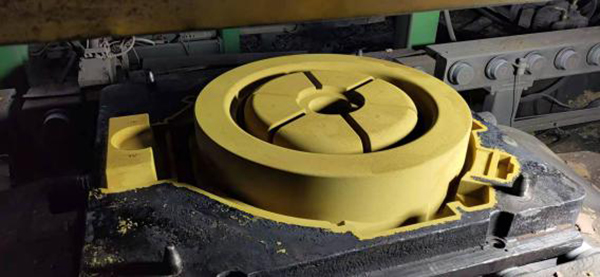

The sand casting process begins with the preparation of a mold. The mold is typically made from a mixture of sand, clay, and water, which allows it to hold its shape during the metal pouring process. A pattern is created, generally out of metal or plastic, that serves as the shape of the component being manufactured. Once the mold is ready, molten metal is poured into it, and after cooling and solidification, the mold is broken away to reveal the cast part.

One of the primary advantages of sand casting is its ability to produce large and complex parts that may be difficult or expensive to create using other manufacturing methods. The process is highly adaptable, capable of casting a variety of metals such as aluminum, iron, and steel.

The Advantages of China’s Sand Casting Factories

China's sand casting factories benefit from several advantages that contribute to their leadership in this sector. Firstly, the country has abundant natural resources, including vast reserves of sand that are essential for mold production. Coupled with competitive labor costs, these factors contribute to the lower overall production costs.

Moreover, China has made significant investments in modernizing its foundries. Many factories have adopted advanced technologies, such as computer numerical control (CNC) machines and automation, which enhance precision and efficiency. These innovations allow Chinese manufacturers to produce high-quality castings that meet international standards. Additionally, the use of foundry management software helps to streamline operations, reduce waste, and improve production times.

china sand casting factory

Global Implications and Market Reach

As a result of these advantages, Chinese sand casting factories have established a strong presence in global markets. They supply components for various industries, from automotive and aerospace to machinery and electronics. Companies around the world often turn to Chinese manufacturers for their ability to produce large volumes of precision parts at competitive prices.

However, this global reach also comes with challenges. Increased scrutiny over environmental practices has led to significant reforms in how factories operate. China has imposed stricter regulations on emissions and waste management, pushing factories to adopt more sustainable practices. Many manufacturers are now investing in green technologies, such as electric furnaces and sand recycling systems, to reduce their environmental impact.

Challenges and Future Direction

Despite their strengths, sand casting factories in China face challenges such as fluctuating raw material costs and rising labor expenses. Additionally, competition from other low-cost manufacturing countries can threaten market share. To navigate these challenges, many manufacturers are focusing on innovation, embracing new technologies, and expanding their capabilities to include value-added services like machining and assembly.

Looking ahead, the future of China’s sand casting industry appears promising. With ongoing investments in research and development, factories are poised to improve their processes and product offerings continuously. The increasing demand for custom cast parts in various sectors, coupled with advancements in technologies like 3D printing for mold creation, will further drive growth in the industry.

Conclusion

China’s sand casting industry exemplifies the country's manufacturing prowess and its ability to adapt to changing market demands. With its established supply chains, commitment to quality, and innovative practices, Chinese sand casting factories continue to play a pivotal role in the global manufacturing landscape. As they evolve, these factories will likely contribute not only to the economy but also to advancements in sustainable manufacturing practices, setting a benchmark for the industry worldwide. Through relentless pursuit of excellence and environmental stewardship, China stands poised to lead in sand casting for years to come.

Post time:Նյմ . 12, 2024 11:52

Next:foundry molding sand