The Importance of Sanding 3D Prints A Comprehensive Guide

3D printing has revolutionized the way we create and design objects, allowing for intricate shapes and customized items that were once inconceivable. However, to achieve a professional finish, especially for functional prototypes or artistic endeavors, post-processing techniques like sanding play a crucial role. This article explores the importance of sanding in 3D printing, the techniques involved, and tips for achieving the best results.

Why Sanding is Necessary

When a 3D print is completed, it often exhibits layer lines, rough edges, and other imperfections due to the additive manufacturing process. These issues can be particularly pronounced when using filament materials like PLA, ABS, or PETG, which do not always yield a smooth surface finish straight out of the printer. Sanding is essential not only to enhance the aesthetic appeal of the final product but also to improve its functionality and comfort, especially for objects intended for use in fashion or as ergonomic components.

Additionally, sanding helps to prepare the print for further finishing processes, such as painting or sealing. A smoother surface adheres better to paints and coatings, resulting in a more professional appearance. For designers and inventors, a well-finished prototype not only reflects well on their skills but also enhances their credibility when presenting to investors or clients.

Choosing the Right Tools and Materials

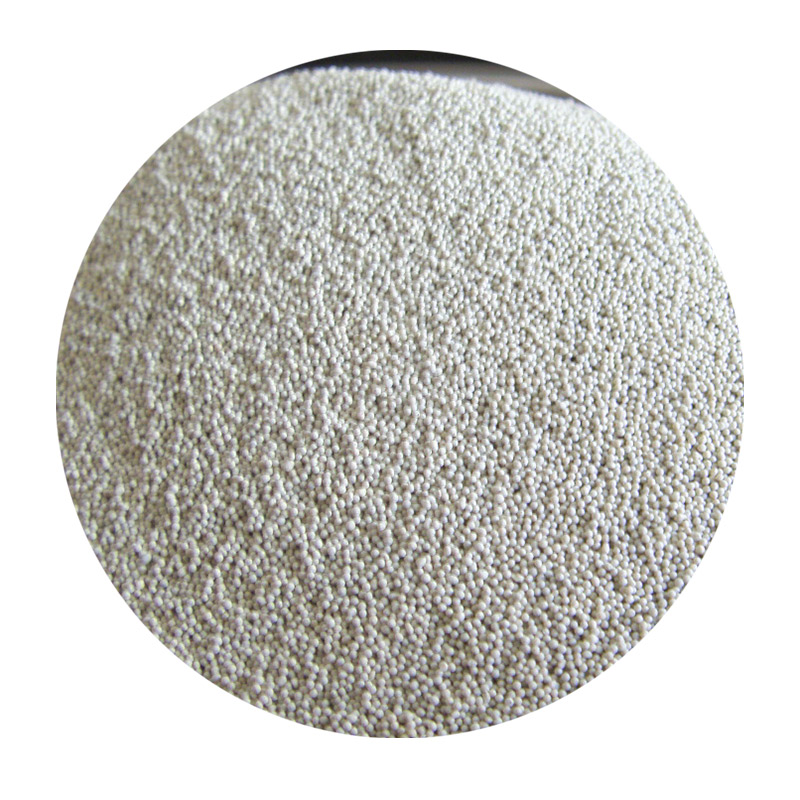

Before beginning the sanding process, it is essential to select the appropriate tools and materials. Sandpaper is typically categorized by its grit, which indicates the size of the abrasive particles. For 3D prints, you might start with a lower grit (about 80-120) to remove major imperfections and build up to high grit (up to 1000 or more) for a smooth finish.

In addition to sandpaper, sanding sponges are an excellent alternative because their flexible structure allows them to conform to the contours of the object. Power tools, like rotary sanders, can also be beneficial for larger or more rugged prints, but they require a careful touch to avoid damaging the print.

The Sanding Process

sanding 3d prints

1. Preparation Before you start sanding, ensure that the print is clean and free from any debris. Use a soft brush or a cloth to remove dust and particles.

2. Initial Sanding Begin with a coarser sandpaper (around 80-120 grit) to remove any visible lines or rough edges. Sand in a circular or back-and-forth motion, being careful not to apply too much pressure as this can result in uneven surfaces.

3. Progressive Sanding Once the major imperfections are addressed, switch to finer grit sandpaper (220 grit and above) to smooth out the surface. This progressive sanding method—moving from coarse to fine—allows you to achieve a more polished finish.

4. Wet Sanding For an even finer finish, consider wet sanding, which involves using water or a lubricant with sandpaper. This technique reduces dust and helps achieve a glass-like surface by preventing the sandpaper from clogging.

5. Cleaning Up After sanding, clean the print again to remove any remaining dust or grit. This step is crucial before applying any paint or finishing touches.

Final Touches

After sanding, many people opt for additional finishing techniques such as painting, priming, or applying a sealant. Choosing the right paint type is important; for example, acrylic paints work well on most plastics. Ensure to apply several thin coats rather than one thick coat to prevent running and ensure an even finish.

Conclusion

Sanding may seem like a tedious task, but it's a critical step in the 3D printing process that can make a significant difference in the quality of the final product. By investing time into proper sanding techniques, not only can you enhance the aesthetics of your prints, but you also improve their functionality and durability. With the right tools and methods, achieving a professional finish is within reach for every 3D printing enthusiast. Whether you are a hobbyist or a seasoned professional, mastering the art of sanding will certainly elevate your 3D printing projects to the next level.

Post time:stu . 15, 2024 08:21

Next:foundry sands