Properties of Foundry Sand An Essential Element in Metal Casting

Foundry sand plays a crucial role in the metal casting industry. It is a key material used to create molds and cores for the production of metal parts. Understanding the properties of foundry sand is essential for achieving high-quality castings, improving production efficiency, and minimizing defects in the final products. This article explores the various properties of foundry sand and their importance in the casting process.

Composition of Foundry Sand

Foundry sand is primarily composed of silica (SiO2), which performs well under high temperatures and provides excellent thermal stability. However, it's important to note that foundry sand can also contain other materials, including clay, which binds the sand grains together, and various additives that can enhance certain properties. The type of sand selected often depends on the specific requirements of the casting process and the metal being cast.

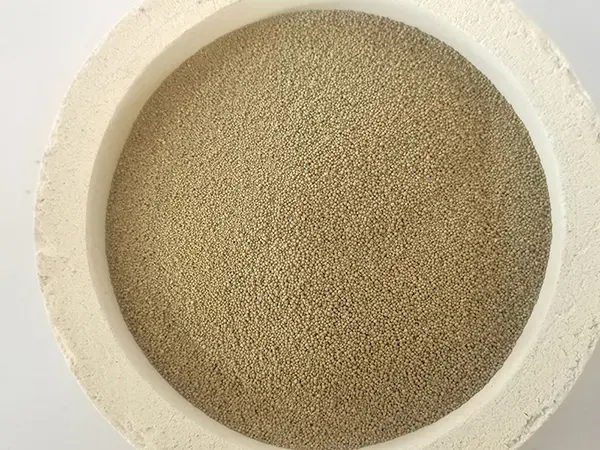

Grain Size and Distribution

One of the most critical properties of foundry sand is its grain size and distribution. Ideally, foundry sand should have a uniform grain size, allowing for effective packing, which is vital for creating strong molds that can withstand the stresses during metal pouring. A well-graded sand mixture, with a range of grain sizes, can help fill voids between larger grains, thereby enhancing the mold's strength and permeability. Grain size affects both the surface finish of the casting and the heat transfer characteristics, influencing the cooling rate of the molten metal.

Permeability

Permeability refers to the ability of the sand mold to allow gases to escape during the casting process. High permeability is essential, as it prevents gas buildup that could result in defects like porosity and blowholes in the final casting. Foundry sand with excellent permeability allows for proper molding of the molten metal and facilitates the release of gases produced during the melting and solidification process. The permeability of sand can be influenced by its grain shape, size, and moisture content.

foundry sand properties

Cohesion and Flowability

Cohesion describes the ability of sand to stick together, which is vital for the stability of the mold. Foundry sand must exhibit sufficient cohesion to maintain its shape when the molten metal is poured into the mold. Additionally, flowability is important for how well the sand can be manipulated during the molding process. Sand that flows easily allows for better mold filling and reduces the likelihood of defects. The presence of additives, like bentonite clay, can enhance the cohesion and flowability of foundry sand, making it a more effective material for casting.

Thermal Properties

Thermal stability is another critical property of foundry sand. The sand must withstand high temperatures without undergoing significant changes in structure or physical properties. When molten metal is introduced into the mold, the temperature can rise significantly, and the sand must maintain its integrity to ensure dimensional accuracy and surface quality in the final casting. Sands with high thermal conductivity help manage heat transfer, which is crucial for the cooling phases of the casting process.

Reusability and Environmental Impact

In recent years, the reusability of foundry sand has gained importance due to environmental concerns and the quest for cost-effective production. Used foundry sand can often be reclaimed and recycled for further casting applications. However, the effectiveness of this recycled sand depends on its properties remaining intact after the initial use. Research into the treatment and processing of used foundry sand has shown potential to enhance its properties and make it a viable option for both environmental sustainability and economic savings.

Conclusion

In conclusion, the properties of foundry sand are essential for successful metal casting. Understanding aspects such as composition, grain size, permeability, cohesion, thermal characteristics, and reusability can significantly influence the quality of castings produced. As the industry continues to evolve, there is a strong push towards sustainable practices and optimizing the use of foundry sand. Therefore, ongoing research and development will play a key role in enhancing foundry sand properties and ensuring high-quality outcomes in metal casting processes. As we strive for better efficiency and sustainability in manufacturing, the importance of high-quality foundry sand will only continue to grow.

Post time:pro . 19, 2024 18:34

Next:Comparing Investment Casting and Sand Casting Techniques for Optimal Manufacturing Solutions