The Importance of Foundry Molding Sand in Metal Casting

Foundry molding sand plays a crucial role in the metal casting process, which is a fundamental manufacturing technique used to produce metal components and parts. This process involves pouring molten metal into a mold cavity, which is formed from a mixture of sand and a binding agent. The choice of sand, its properties, and the techniques involved in sand mold production directly impact the quality, efficiency, and cost-effectiveness of the casting.

Types of Foundry Molding Sand

There are several types of sand used in foundries, each with specific characteristics suited for different casting applications. The most commonly used molding sands include

1. Green Sand This is the most traditional type of sand used in metal casting. It is a mixture of silica sand, clay, and water. Green sand molds are known for their excellent moldability, thermal properties, and ability to retain moisture, which helps in achieving a good finish.

2. Shell Sand Shell sand involves a process where fine sand is coated with a thermosetting resin. The application of heat causes the resin to harden, forming a rigid mold. Shell sand molds provide high dimensional accuracy and a smooth surface finish, making them ideal for complex shapes and fine details.

3. Chemical Bonded Sand This type of sand uses chemical binders instead of traditional clay. The binders are activated by heat or a catalyst, providing an alternative to moisture-based sands. Chemical bonded sands offer greater flexibility in molding and can produce thin-walled castings with intricate designs.

4. Zircon Sand This is a high-performance sand used in casting applications that require superior thermal stability and low thermal expansion. Zircon sand is particularly beneficial for producing castings that withstand high temperatures.

Characteristics of Molding Sand

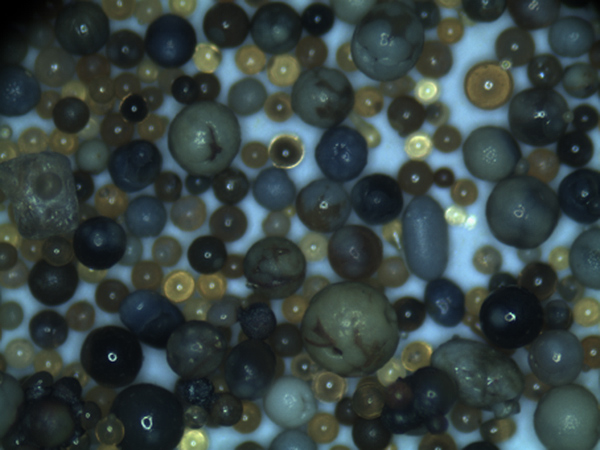

foundry molding sand

The effectiveness of foundry molding sand hinges on various properties that determine its performance in the casting process

. Here are some key characteristics- Grain Size and Shape The size and shape of the sand grains influence the mold's strength and permeability. Typically, a mixture of fine and coarse grains is used to enhance stability while allowing gases to escape during metal pouring.

- Moisture Content The right balance of moisture is critical. Too much moisture can lead to defects like gas holes, while too little can result in poor mold strength and durability.

- Permeability This property allows gases produced during the melting and pouring process to escape, preventing defects in the final casting.

- Clay Content The percentage of clay in the sand affects mold strength, cohesion, and the ability to hold shape. The right proportion is crucial for mold durability and performance during the casting process.

Applications of Foundry Molding Sand

Foundry molding sands are used in various industries, including automotive, aerospace, and general manufacturing. The versatility of molding sand allows for producing a wide range of products, from small components to large structural parts. The adaptability of these sands to different casting techniques, such as sand casting, investment casting, and lost foam casting, makes them a vital material in modern manufacturing.

Conclusion

In conclusion, foundry molding sand is an indispensable material in the metal casting industry. For manufacturers looking to produce high-quality castings, understanding the types of molding sands, their characteristics, and their proper application is essential. As technology advances and the demand for precision casting increases, the development and optimization of molding sand will play a critical role in shaping the future of manufacturing. It is evident that the careful selection and management of foundry molding sand can significantly enhance the overall performance and profitability of casting operations.

Post time:lis . 18, 2024 16:31

Next:resin coated sand uses