Ceramsite Foundry Sand An Innovative Material for Improved Casting Performance

In the modern foundry industry, the search for high-performance materials that enhance the quality of cast products is an ongoing pursuit. Among the various options available, ceramsite foundry sand has emerged as a significant player, offering a range of benefits that can improve both the casting process and the final product. This article explores the properties, advantages, and applications of ceramsite foundry sand, illustrating its role in advancing foundry technology.

What is Ceramsite Foundry Sand?

Ceramsite foundry sand is a type of engineered sand made from clay and other raw materials that are subjected to high temperatures to create small, round ceramic particles. This unique manufacturing process gives ceramsite its distinct properties, making it an ideal choice for various casting applications. Unlike traditional sand materials that can have irregular shapes and varying sizes, ceramsite sand exhibits a uniform particle morphology, which can significantly influence the flowability and compaction of the sand during molding.

Properties of Ceramsite Sand

The physical and chemical properties of ceramsite foundry sand contribute to its effectiveness in foundry applications. Some of the key properties include

1. High Refractoriness Ceramsite foundry sand can withstand high temperatures without deformation, making it suitable for casting metals that require elevated pouring temperatures.

2. Low Thermal Expansion The low thermal expansion coefficient of ceramsite reduces the risk of cracking and distortion during the cooling process, which can enhance the dimensional accuracy of the cast products.

3. Excellent Flowability The round shape and smooth surface finish of ceramsite particles facilitate better flowability, improving the efficiency of the molding process and allowing for more intricate mold designs.

4. High Strength The mechanical strength of ceramsite sand ensures that the mold structure maintains integrity during the pouring and solidification of molten metal.

5. Chemical Stability Ceramsite is chemically inert and resistant to chemical reactions with molten metals, which helps in maintaining the quality of the cast surface.

Advantages of Using Ceramsite Foundry Sand

The use of ceramsite foundry sand offers several advantages over conventional sands, making it an attractive option for foundries

ceramsite foundry sand

1. Improved Surface Finish The fine texture and uniformity of ceramsite particles lead to smoother castings with fewer defects, reducing the need for extensive post-casting finishing work.

2. Enhanced Casting Accuracy The low thermal expansion and high strength of ceramsite sand contribute to dimensional stability, resulting in more accurate casts that meet stringent quality specifications.

3. Reduced Environmental Impact Ceramsite foundry sand is often produced from abundant raw materials and may be more environmentally friendly compared to traditional alternatives, especially when recycled properly.

4. Cost Efficiency While the initial investment in ceramsite sand may be higher, the long-term benefits, including lower defect rates and reduced finishing costs, can lead to overall cost savings for foundries.

Applications of Ceramsite Foundry Sand

Ceramsite foundry sand is versatile and can be utilized in various casting processes, including

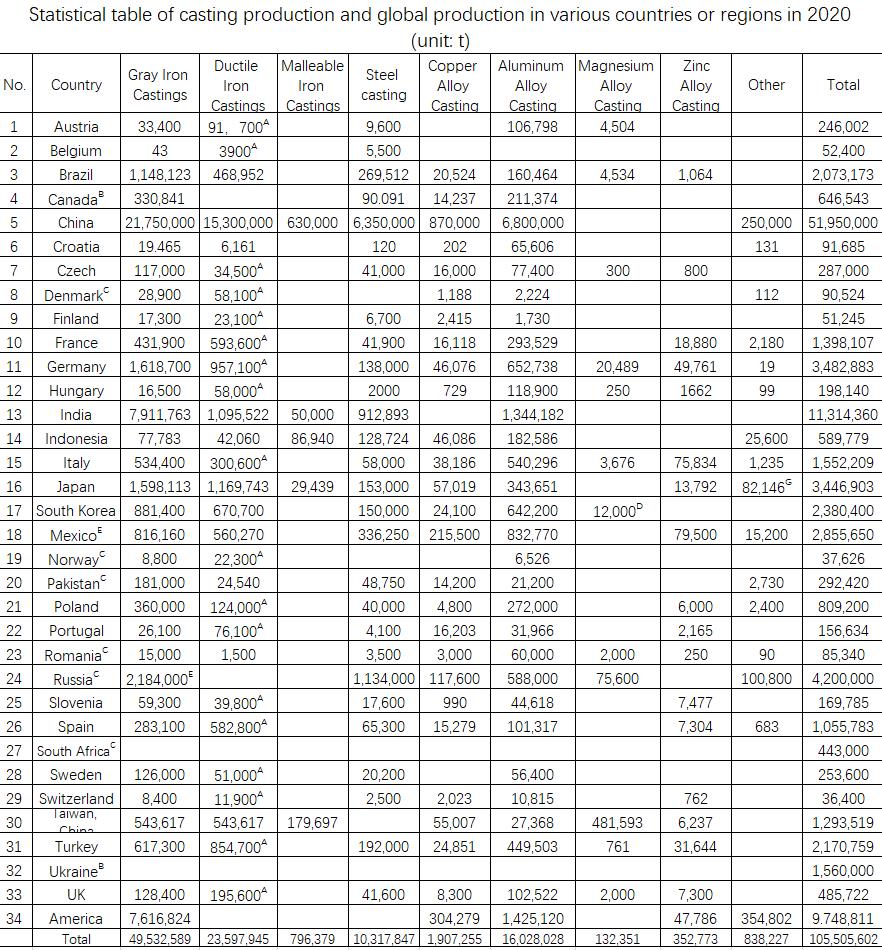

1. Iron and Steel Casting The high-temperature resistance of ceramsite makes it ideal for casting ferrous metals, where precision and surface quality are critical.

2. Non-ferrous Casting Ceramsite is also suitable for non-ferrous metals like aluminum and copper, where its properties help in achieving optimal casting characteristics.

3. Investment Casting In investment casting processes, ceramsite sand can improve mold quality and surface finish, enhancing the precision of detailed components.

4. Shell Molding The rapid cooling rates and thermal stability of ceramsite are beneficial in shell molding applications, where thin-walled, complex shapes are required.

Conclusion

In conclusion, ceramsite foundry sand represents a significant advancement in foundry materials, offering numerous benefits that enhance casting performance. Its unique properties, including high refractoriness, low thermal expansion, and excellent flowability, position it as a superior alternative to traditional foundry sands. As the foundry industry continues to evolve, the adoption of innovative materials like ceramsite foundry sand will play a crucial role in meeting the demands for high-quality castings while promoting sustainable practices. Embracing this advanced material is not just an option but a necessity for foundries aiming for excellence in their production processes.

Post time:pro . 30, 2024 23:34

Next:difference between sand casting and permanent mold casting