Sand Printing Casting Revolutionizing Manufacturing Techniques

In recent years, the manufacturing industry has witnessed significant advancements in technology, particularly in the realm of casting processes. One of the most innovative methods that have emerged is sand printing casting, a technique that combines traditional sand casting with cutting-edge 3D printing technology. This unique approach is transforming the way we produce metal components, offering benefits that traditional methods struggle to match.

What is Sand Printing Casting?

Sand printing casting is a hybrid technique that uses 3D printing to create sand molds for casting metal parts. Instead of relying on traditional patterns or molds, manufacturers can now use additive manufacturing to directly print the sand forms required for casting. This method offers a level of precision and customization that was previously unattainable with conventional sand casting techniques. By leveraging the capabilities of 3D printing, engineers can produce intricate geometries and complex structures that are tailored to specific applications.

Advantages of Sand Printing Casting

1. Design Freedom One of the most significant advantages of sand printing casting is the enhanced design freedom it offers. Engineers can create intricate designs that would be challenging or impossible to achieve with traditional casting methods. This allows for lighter, stronger components that can be optimized for their intended use.

2. Reduced Lead Times Traditional sand casting often involves lengthy setup times, including pattern creation and mold preparation. With sand printing casting, these lead times are significantly reduced. The ability to quickly produce molds directly from digital files means that prototypes can be tested and modified in real-time, accelerating the overall product development process.

3. Material Efficiency Sand printing casting minimizes waste by producing molds only as needed, unlike traditional methods where excess material can lead to increased waste. This efficiency not only reduces costs but also contributes to more sustainable manufacturing practices.

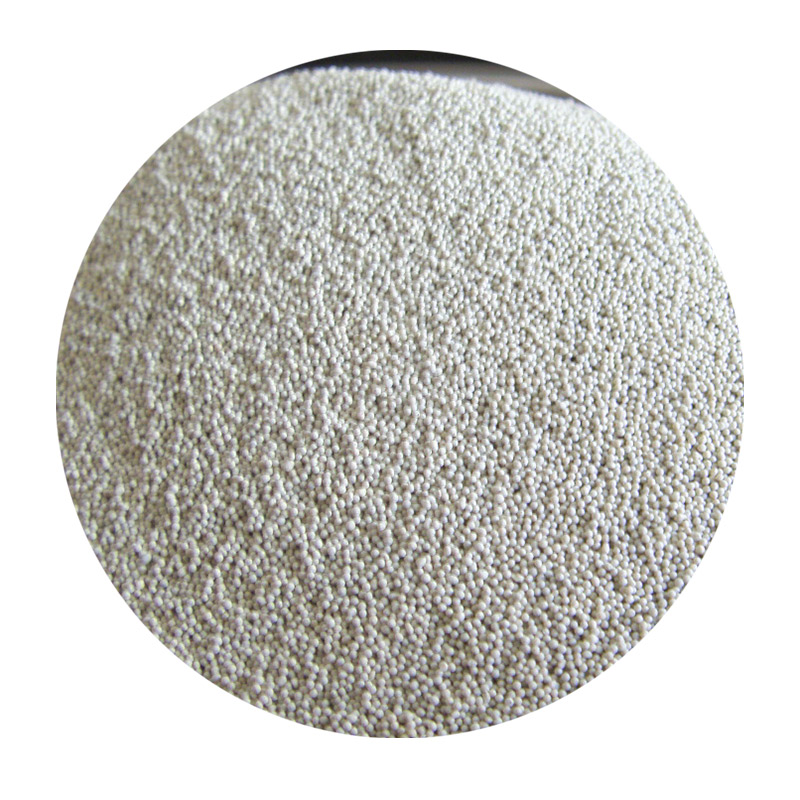

sand printing casting

4. Customization In many industries, the demand for customized solutions is on the rise. Sand printing casting allows manufacturers to easily create tailor-made parts for specific applications without the need for extensive retooling. This adaptability can be especially beneficial in sectors like aerospace, automotive, and medical devices, where unique specifications are paramount.

5. Enhanced Quality The precision of 3D printing technologies translates into higher quality molds, which in turn leads to improved casting outcomes. Components produced through sand printing casting often exhibit better surface finishes and dimensional accuracy compared to those made through traditional methods.

Applications of Sand Printing Casting

The applications of sand printing casting are vast and varied. Industries such as aerospace and automotive are already exploring its potential for producing lightweight components that meet strict performance standards. Additionally, the medical field can benefit from this technology by creating customized implants and devices that cater to the specific needs of patients.

The Future of Sand Printing Casting

As the technology behind sand printing casting continues to evolve, its impact on the manufacturing industry is expected to grow. Innovations in materials and techniques will further enhance the capabilities of this casting method, opening new avenues for production and design. Furthermore, as more industries recognize the benefits of this approach, we can anticipate a shift in traditional manufacturing paradigms towards more efficient and innovative practices.

In conclusion, sand printing casting is not merely a trend; it represents a foundational shift in the way we approach manufacturing. By embracing this technology, industries can achieve greater efficiency, enhanced quality, and unparalleled design freedom. As we move forward, sand printing casting will undoubtedly play a pivotal role in shaping the future of production, making it an exciting area to watch for developments and breakthroughs.

Post time:नवम्बर . 09, 2024 02:59

Next:Affordable Casting Sand Available for Purchase Online or In-Store Today