Sand Sintering An Overview of Processes and Applications

Sand sintering is a critical process in the field of materials science and engineering, particularly in the production of various ceramic and composite materials. This technique involves the compacting and heating of sand particles to achieve a densified mass, which possesses enhanced strength and durability compared to the individual particles. This article explores the fundamentals of sand sintering, its mechanisms, benefits, and applications in various industries.

Mechanisms of Sand Sintering

The sintering process begins with the arrangement of sand particles into a desired shape, which is then subjected to heat. During sintering, the particles begin to adhere to one another through various mechanisms, such as diffusion, grain boundary movement, and viscous flow. As the temperature rises, the mobility of the particles increases, allowing the surfaces to bond more effectively. This bonding reduces the porosity of the material and increases its overall density and mechanical strength.

The temperature at which sintering occurs is crucial; it must be sufficiently high to facilitate particle bonding but not so high that it leads to the melting of the material. The choice of any additives, such as binders or fluxes, can also influence the sintering process by altering the flow characteristics of the sand particles and enhancing bonding.

Benefits of Sand Sintering

One of the primary advantages of sand sintering is the ability to create complex shapes and structures with high dimensional accuracy. This makes it an invaluable technique for producing components in various industries, including construction, aerospace, and automotive. Furthermore, sintered sand materials exhibit excellent thermal stability and wear resistance, making them suitable for high-performance applications.

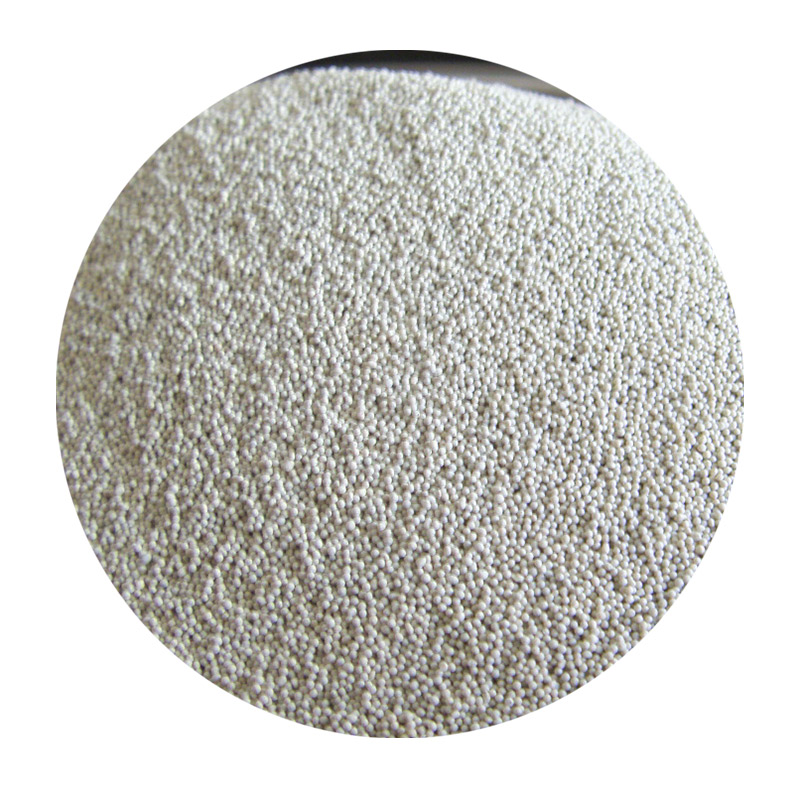

sand sintering

Additionally, sand sintering can utilize a variety of raw materials, including recycled sand, which promotes sustainability and reduces environmental impact

. The process also allows for the incorporation of different additives that can impart specific properties to the final product, such as improved chemical resistance or enhanced thermal insulation.

Applications of Sand Sintering

The applications of sand sintering are vast and varied. In the construction industry, sintered sand is commonly used to produce building blocks and bricks that offer enhanced durability compared to traditional materials. These products are particularly beneficial in regions with extreme weather conditions, as they are less prone to degradation over time.

In the aerospace and automotive industries, sand sintering is employed to manufacture components that require high mechanical strength and thermal resistance. For example, sintered parts might be used in engines, where they must withstand elevated temperatures and pressures.

Moreover, sand sintering plays a role in the development of advanced materials, such as those used in 3D printing. The additive manufacturing community often relies on sintering techniques to produce intricate and lightweight components that are tailored for specific applications.

Conclusion

In summary, sand sintering is a significant process that harnesses the unique properties of sand particles to create superior materials for a variety of applications. Its ability to form complex structures with enhanced strength and durability makes it a valuable tool in modern manufacturing. As research continues to evolve in this field, the potential for new techniques and applications is immense, promising to unlock even greater possibilities in material science and engineering. By investing in sand sintering technology, industries can promote sustainability while producing high-quality products that meet the demanding needs of today’s market.

Post time:דצמ . 10, 2024 15:20

Next:Exploring the Density of Foundry Sand and Its Impact on Casting Processes