Materials Used for Sand Casting

Sand casting is a widely used manufacturing process that involves the creation of metal components through the pouring of molten metal into a sand mold. This method is favored in many industries for its ability to produce intricate designs and large components with relatively low costs. The selection of appropriate materials is crucial to ensure quality and efficiency in the sand casting process. This article explores the key materials used in sand casting, highlighting their significance and characteristics.

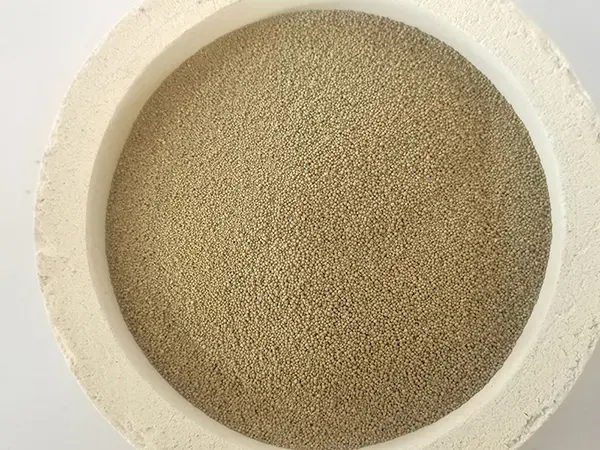

1. Sand

The primary material used in sand casting is sand itself, specifically silica sand. Silica sand is preferred because it offers excellent thermal stability and the ability to withstand high temperatures. The grain size, shape, and composition of the sand can significantly affect the quality of the mold and the final casting. For optimal results, sand is often mixed with a binder, typically clay or resin, to enhance its ability to hold the shape of the mold. Green sand, which contains approximately 90% silica, 5% clay, and 5% water, is a common choice for many casting applications.

2. Binders

Binders are crucial in sand casting as they help to hold the sand grains together and maintain the mold's shape during the pouring of molten metal. There are various types of binders used in the industry, including

- Clay Binders Natural clays, such as bentonite, are often used due to their excellent adhesive properties and ability to retain moisture. They are effective in creating flexible molds that can withstand the pouring process.

- Synthetic Binders These include resins and polymer-based binders that offer improved properties such as faster curing times, less emissions, and greater mold strength. They are particularly popular in more modern casting processes, like cold box and no-bake systems.

3. Metal Alloys

The choice of metal alloy is a fundamental aspect when it comes to the final properties of the cast components. Common metals used in sand casting include

materials used for sand casting

- Cast Iron Known for its excellent castability and machinability, cast iron is often employed for making engine blocks, pipes, and other heavy machinery components

.- Aluminum Alloys Lightweight and resistant to corrosion, aluminum alloys are frequently used in automotive and aerospace applications. They can be easily molded and provide good surface finishes.

- Bronze and Brass These copper-based alloys are used for their excellent wear resistance and aesthetic appeal, making them common choices for decorative items and marine components.

4. Additives and Coatings

To enhance the quality of the castings, various additives and coatings are used. These include

- Graphite Often added to improve mold release and decrease sticking of the molten metal to the mold.

- Refractory Coatings These coatings are applied to the inner surfaces of the mold to improve thermal resistance and reduce erosion caused by the molten metal.

- Release Agents These are used to facilitate the easy removal of the casting from the sand mold, reducing defects and improving surface quality.

Conclusion

In summary, the materials used in sand casting play a critical role in ensuring the success of the process. The choice of sand type, binders, metal alloys, and other additives can significantly impact the quality, efficiency, and performance of the final product. By understanding these materials and their properties, manufacturers can optimize their sand casting operations to produce high-quality components that meet the stringent demands of various applications. As technology progresses, innovations in material science continue to enhance the capabilities of sand casting, making it a vital method in modern manufacturing.

Post time:נוב . 11, 2024 18:27

Next:golden sanda