Lost Foam Casting A Revolutionary Technique in Metal Casting

Lost foam casting (LFC) is an innovative metal casting process that provides a seamless solution to many traditional metalworking challenges. This sophisticated technique has gained tremendous traction in various industries, including automotive, aerospace, and general manufacturing, due to its ability to produce intricate shapes with high precision and minimal waste.

The Process of Lost Foam Casting

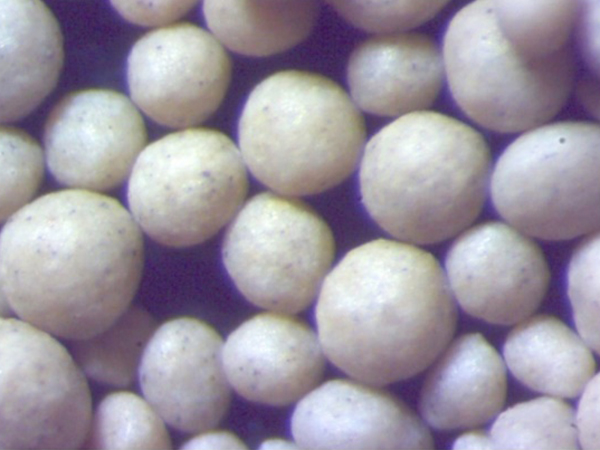

The lost foam casting process begins with the creation of a foam pattern, typically made from polystyrene. This pattern is designed with the exact dimensions of the final metal casting. The foam is then coated with a sand mixture that allows for the formation of a mold. The coated pattern is heated, causing the foam to evaporate, leaving behind a cavity that mirrors the foam's shape.

Once the mold is ready, molten metal is poured into the cavity. As the metal fills the mold, it displaces the vaporized foam, thereby producing a cast identical to the original pattern. This methodology eliminates the need for a separate, solid pattern, which is a hallmark of traditional casting techniques.

Advantages of Lost Foam Casting

Lost foam casting offers several distinct advantages over conventional metal casting methods

1. Complex Shapes One of the most significant benefits of LFC is its ability to produce complex geometries that would be challenging or impossible to achieve with traditional casting techniques. The foam pattern can be easily shaped, allowing for intricate designs without the need for multiple parts.

2. Reduced Waste Traditional casting methods often generate considerable waste due to excess material and the need for machining after casting. In contrast, LFC minimizes waste since it uses the foam pattern that evaporates entirely, leaving no solid remnants behind.

3. High Precision The lost foam technique provides a high level of dimensional accuracy, reducing the need for extensive machining. This precision is invaluable in industries where every millimeter counts, such as in automotive and aerospace applications.

lost-foam casting

4. Cost-Effectiveness While the initial investment in foam patterns may seem high, the overall cost-effectiveness of LFC becomes apparent when considering the savings on materials, machining, and labor costs. The reduction in finishing work significantly lowers production costs.

5. Environmental Considerations As industries increasingly focus on sustainability, LFC stands out for its environmentally friendly process. The elimination of solid patterns and the reduced waste associated with the technique contribute to greener manufacturing practices.

Applications of Lost Foam Casting

Lost foam casting is widely used across various sectors. In the automotive industry, it is employed to produce engine blocks, cylinder heads, and other critical components that require complex shapes and lightweight structures. In aerospace, LFC enables the production of intricately designed parts that can withstand extreme conditions without excessive weight.

The technique is also finding applications in the manufacturing of artistic sculptures and custom items where originality and detail are paramount. Furthermore, its adoption in the production of replacement parts for machinery highlights its versatility in meeting diverse industrial needs.

Challenges and Future of Lost Foam Casting

Despite its advantages, lost foam casting is not without challenges. The process requires careful temperature control and timing to ensure that the metal correctly fills the mold before the foam completely vaporizes. Additionally, achieving a smooth surface finish can be difficult, and certain materials, such as high-melting-point metals, may not be ideal for this technique.

The future of lost foam casting looks promising, thanks to advancements in materials science and 3D printing technology. The integration of these technologies may lead to further enhancements in pattern production and mold-making efficiency, opening new avenues for the application of LFC.

Conclusion

In conclusion, lost foam casting represents a significant advancement in the field of metal casting, combining innovation with efficiency to meet the demands of modern manufacturing. Its ability to produce complex shapes with minimal waste and high precision makes it an invaluable tool across various industries. As technology continues to evolve, the potential for lost foam casting is boundless, paving the way for new applications and improved manufacturing processes.

Post time:נוב . 19, 2024 12:30

Next:buy sand casting