Understanding Steel Sand Casting Suppliers

In the manufacturing and engineering sectors, finding reliable suppliers for materials and components is crucial. Among various manufacturing techniques, sand casting has stood the test of time for its versatility and effectiveness, especially when it comes to producing steel components. This article will delve into the significance of steel sand casting suppliers in today's marketplace, addressing their roles, advantages, and considerations for businesses seeking these services.

What is Steel Sand Casting?

Steel sand casting is a process that involves creating a mold from sand to cast metal objects. It is a widely used method to produce complex shapes and designs that may be challenging or costly to achieve through other manufacturing techniques. This process begins with creating a pattern, usually made from metal, which is then covered in a sand mixture to form a mold. Once the mold is ready, molten steel is poured into it, solidifying into the desired shape.

The Role of Steel Sand Casting Suppliers

Steel sand casting suppliers play a pivotal role in the manufacturing chain. They provide not only the raw materials needed for the sand casting process but also the expertise required to produce high-quality castings. Reliable suppliers offer an array of products, including different types of steel, sand mixtures, and auxiliary materials that ensure the casting process runs smoothly. Additionally, they often provide services related to mold design, casting production, and finishing processes.

Advantages of Working with Esteemed Suppliers

1. Quality Assurance Reputable steel sand casting suppliers maintain rigorous quality control standards. This ensures that the components produced meet industry specifications and are reliable for use in various applications such as automotive, aerospace, and machinery manufacturing.

2. Customization Many suppliers offer customized solutions based on specific project requirements. This adaptability can be incredibly beneficial for businesses that need unique parts or have specific demands regarding size, shape, and material composition.

3. Efficiency Experienced suppliers typically have streamlined processes that enhance production efficiency. This can lead to faster turnaround times, which is crucial in industries where time is of the essence.

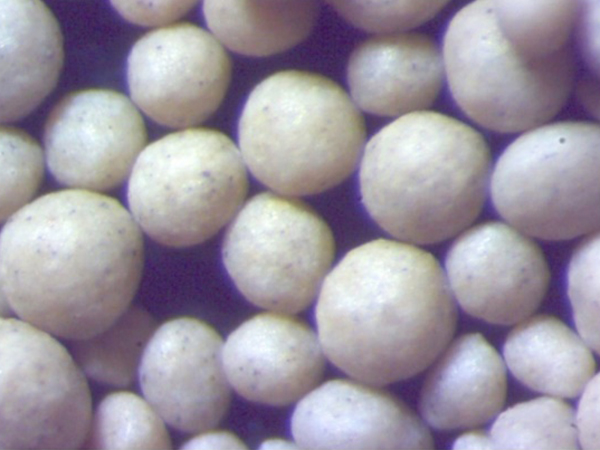

steel sand casting suppliers

4. Technical Support A good supplier doesn’t just provide materials; they also offer technical assistance. From design consultation to troubleshooting during production, having access to expert advice can save both time and resources.

Considerations When Choosing Steel Sand Casting Suppliers

When selecting a steel sand casting supplier, businesses should consider several factors

- Reputation Look for suppliers with a solid track record and positive customer reviews. Testimonials and case studies can provide insights into a supplier's reliability and quality.

- Capabilities Assess whether the supplier has the capacity to handle your specific project scale. This includes evaluating their production capabilities and technological advancements.

- Lead Time and Costs Analyze the lead times and pricing structures. While premium quality may come at a higher price, it's essential to balance cost with quality, especially for crucial components.

- Sustainability Practices In today's environmentally conscious market, suppliers that employ sustainable practices can add value to your projects. This may include responsible sourcing of materials and eco-friendly production methods.

Conclusion

In conclusion, steel sand casting suppliers are integral to the manufacturing process, offering essential materials and expertise. By carefully selecting a reputable supplier, businesses can ensure high-quality steel components that meet their specific needs, ultimately contributing to the success and efficiency of their operations. As industries continue to evolve, the demand for reliable casting solutions will remain a critical factor in manufacturing success.

Post time:સપ્ટેમ્બર . 19, 2024 10:16

Next:الطباعة ثلاثية الأبعاد للرمال - ابتكارات في عالم التصنيع