The Versatility of Spherical Sand An In-Depth Exploration

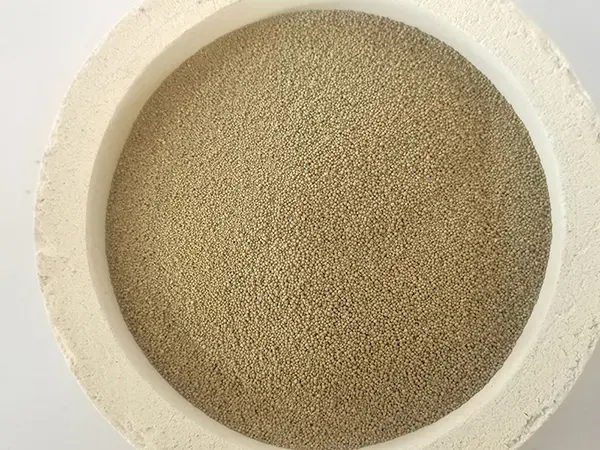

Spherical sand, a unique form of granular material, has recently gained significant attention across various industries. Unlike traditional sand, which often comes in irregular shapes, spherical sand boasts a more uniform spherical structure, leading to numerous advantages in applications ranging from casting to cosmetics. This article delves into the characteristics, production methods, and diverse applications of spherical sand, highlighting its role in contemporary industry and innovation.

Characteristics of Spherical Sand

The primary distinction between spherical sand and conventional sand lies in its shape. The spherical structure reduces inter-particle friction, allowing for better flow characteristics. This property is particularly advantageous in applications where uniformity and flowability are critical. Additionally, spherical sand often features a smooth surface, minimizing wear and tear on machinery and improving material handling processes.

Another significant characteristic of spherical sand is its size uniformity. Most spherical sand grains possess a consistent diameter, which is essential for ensuring uniform mixing and processing in various applications. This uniformity can lead to improved performance in diverse areas, making spherical sand a preferable choice over traditional sand varieties.

Production Methods

Spherical sand is typically produced through advanced manufacturing techniques. One common method involves the use of silica or other natural materials, which are subjected to high temperatures and specialized processing. This process not only shapes the sand particles into spheres but also enhances their physical and chemical properties.

Another innovative approach involves the use of 3D printing technology, which allows for precise control over the size and shape of the sand particles. This method ensures that the spherical sand meets specific industry standards and requirements, catering to the diverse needs of various applications.

Applications of Spherical Sand

spherical sand

The versatility of spherical sand makes it suitable for a wide range of applications

1. Casting and Molding In metal casting, spherical sand is often used as a molding material. Its excellent flowability and ability to fill molds uniformly result in high-quality casts with minimal defects. This property makes it a preferred choice for precision engineering industries.

2. Oil and Gas Exploration Spherical sand is utilized in hydraulic fracturing (fracking) processes. Its shape helps to maintain the structural integrity of the fractures in the rock formations, facilitating the extraction of oil and gas. The uniformity of the particles also ensures better permeability, improving the efficiency of the extraction process.

3. Cosmetics and Personal Care In the beauty industry, spherical sand is increasingly used as an exfoliant due to its gentle nature and ability to provide a smooth application. Its rounded shape minimizes the risk of skin irritation, making it a popular choice for scrubs and cleansers.

4. Abrasives Spherical sand is also used in abrasive applications, including sandblasting, where its uniform and smooth particles provide effective cleaning and finishing of surfaces without causing damage.

5. Additive Manufacturing The burgeoning field of 3D printing utilizes spherical sand in various processes, where its consistent shape and size facilitate precise layer deposition and structural integrity.

Conclusion

Spherical sand represents a significant advancement in the realm of granular materials. With its unique properties, production methods, and diverse applications, it has carved out a vital niche in industries such as casting, oil and gas, cosmetics, abrasives, and 3D printing. As industries continue to innovate and seek materials that enhance efficiency and product quality, the demand for spherical sand is likely to grow, paving the way for new applications and further research into this fascinating material. The future looks promising for spherical sand, as its versatility and performance capabilities reshape the landscape of various industrial processes.

Post time:ડીસેમ્બર . 03, 2024 21:24

Next:Whispers of the Shimmering Shoreline