Understanding Sintered Sand A Sustainable Solution in Modern Manufacturing

In the realm of modern manufacturing, the pursuit of innovative materials that balance functionality, sustainability, and cost-effectiveness is an ever-evolving challenge. One such material that has gained attention in recent years is sintered sand. This unique composite material is derived from the natural properties of sand, which undergoes a transformative process known as sintering. This article aims to explore what sintered sand is, its production process, and its numerous applications in various industries.

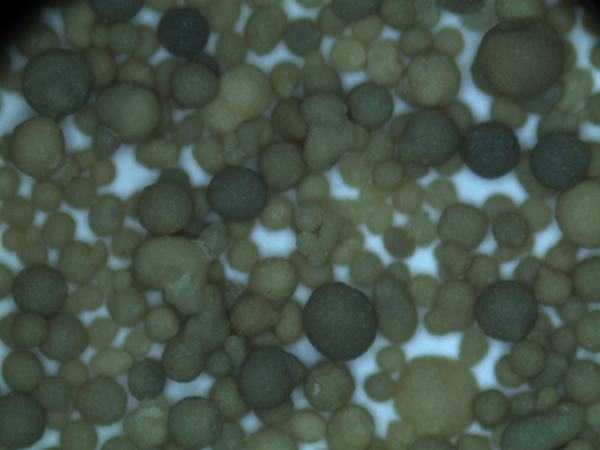

Sintering is a process that involves heating materials below their melting points, allowing them to fuse together without fully liquidizing. In the case of sand, this means using heat to bond the fine particles, creating a coherent structure that maintains the properties of its original form. The process can be enhanced through the addition of binders or chemical agents, which improve the strength and integrity of the final product. Sintered sand exhibits remarkable durability and can withstand considerable mechanical stress, making it an appealing alternative to conventional materials.

One of the most significant advantages of sintered sand is its environmental benefits. Traditional manufacturing processes often rely on non-renewable resources or generate substantial waste. In contrast, sintered sand can be produced from recycled sand and other by-products, significantly reducing the need for virgin materials. This not only decreases extraction rates of natural resources but also minimizes landfill waste, aligning with the global push toward more sustainable production practices.

sintered sand

Moreover, sintered sand serves a multitude of applications across various industries

. In the construction sector, it is frequently utilized as a lightweight aggregate for concrete, enhancing the material's insulation properties while reducing the overall weight of structures. This is particularly valuable in the construction of energy-efficient buildings, where reduced material weight can lead to lower energy consumption during heating and cooling.The oil and gas industry also benefits from sintered sand, particularly in the process of hydraulic fracturing, commonly known as fracking. Sintered sand serves as a proppant, keeping fractures open within geological formations to facilitate the extraction of oil and gas. By providing a sturdy and reliable alternative to traditional proppants, sintered sand enhances the efficiency and safety of drilling operations.

In addition to its industrial applications, sintered sand is increasingly being explored for use in the creation of art and decorative items. Artists and sculptors are experimenting with this medium, taking advantage of its unique texture and strength to produce innovative designs that stand the test of time.

In conclusion, sintered sand represents a compelling advancement in material science, illustrating how traditional resources can be repurposed into innovative solutions. With its impressive strength, sustainability, and versatility, sintered sand is poised to play a significant role in the future of manufacturing and construction. As industries continue to seek greener alternatives, sintered sand exemplifies the potential for creating functional, eco-friendly materials that contribute to a more sustainable world.

Post time:સપ્ટેમ્બર . 12, 2024 20:14

Next:Sand Casting - Технологияи рехтани орд барои истеҳсоли қисмҳои дақиқ