Exploring the Fascinating World of Sand 3D Printing

In recent years, the field of 3D printing has witnessed groundbreaking advancements, one of the most intriguing being the utilization of sand as a primary material. Sand 3D printing merges traditional techniques with modern technology, opening up a world of possibilities across various industries. This innovative approach not only revolutionizes manufacturing but also addresses pressing sustainability challenges.

Exploring the Fascinating World of Sand 3D Printing

One of the most significant benefits of sand 3D printing lies in its environmental impact. Traditional manufacturing methods often involve extensive waste generation, as excess materials are discarded during the shaping process. In contrast, sand 3D printing generates minimal waste, as the surplus sand can be reused in subsequent prints. Moreover, the abundance of sand as a raw material makes this process more sustainable. It is not only cost-effective but also reduces the environmental footprint associated with sourcing and transporting materials.

sand 3d

The versatility of sand 3D printing has opened doors in various sectors, particularly in construction and foundry applications. In construction, companies are exploring the use of sand 3D printing to create intricate architectural components and even entire buildings. This technology allows for rapid prototyping, enabling architects to visualize their designs in a tangible form, facilitating creative exploration while reducing construction timelines.

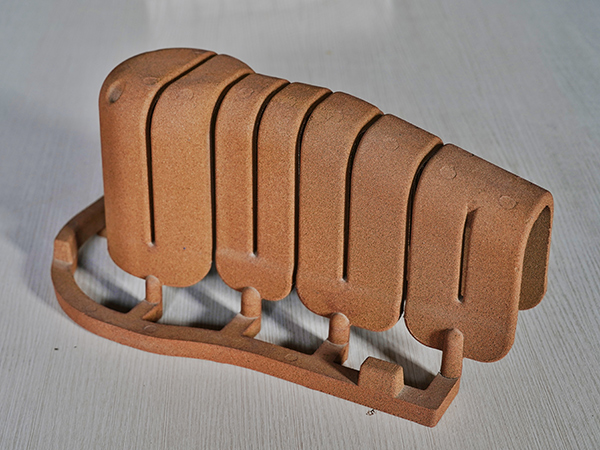

In the foundry industry, sand 3D printing is revolutionizing the production of metal casting molds. Traditional mold-making processes involve significant time and labor, often leading to delays and increased costs. With sand 3D printing, foundries can produce customized molds quickly and efficiently, enhancing productivity and allowing for greater design flexibility. This advancement also contributes to the creation of lighter, more intricate metal components, further pushing the boundaries of engineering design.

As we look to the future, the applications of sand 3D printing are expanding beyond construction and foundry work. Research is ongoing to delve into its potential use in creating eco-friendly, low-energy housing solutions that utilize locally sourced materials, demonstrating a sustainable approach to modern living.

In conclusion, sand 3D printing stands at the intersection of innovation and sustainability, representing a significant leap forward in manufacturing technology. By harnessing the unique properties of sand, experts in various fields are discovering new ways to create complex, efficient, and environmentally friendly products. As this technology continues to evolve, its potential to transform industries and contribute to a more sustainable future becomes ever more promising. The sand 3D printing revolution is just beginning, and its impacts will surely be felt across the globe for years to come.

Post time:ઓક્ટોબર . 07, 2024 00:32

Next:gold sands