Different Types of Sand Casting

Sand casting is a versatile and widely employed manufacturing process that involves pouring molten metal into a sand mold to create a desired object. This technique is known for its ability to produce complex shapes and is utilized in various industries, from automotive to aerospace. While sand casting might seem straightforward, there are multiple types of sand casting processes, each with its unique characteristics and advantages. This article will explore several different types of sand casting methods and their applications.

1. Green Sand Casting

Green sand casting is one of the most common types of sand casting. It utilizes a mixture of sand, clay, and water to form the mold. The term green refers to the mold's moisture content; it is not fully dried before molten metal is poured in. This method is favored for its cost-effectiveness and ease of use. Green sand molds can be easily reused, making them an environmentally friendly option. Additionally, the process allows for excellent detail reproduction, making it suitable for small to medium-sized production runs.

Unlike green sand casting, dry sand casting involves drying the mold before the molten metal is poured in. This is achieved by using heat to harden the sand and bind it together. Dry sand molds offer better dimensional accuracy and surface finish compared to green sand molds. They also can withstand higher temperatures, making them ideal for certain alloys and high-precision applications. Dry sand casting is often employed in industries where high-quality finishes and reliability are paramount.

3. Skin-dried Sand Casting

different types of sand casting

Skin-dried sand casting is a hybrid method that combines elements of both green and dry sand casting. In this process, the mold is first formed using green sand, but a thin layer of the mold is dried using heat. The result is a mold that has a hard outer layer, providing better surface quality, while still retaining the reusable and forgiving properties of green sand. This technique allows for improved detail and a smoother finish, making it suitable for various applications, including artistic casting and small batch production.

4. Core Sand Casting

Core sand casting involves the use of cores made from sand and a binding agent. Cores are used to create internal cavities or complex features within the molded part. The use of cores is particularly beneficial when designing parts that require hollow sections, such as engine blocks or pipes. Core sand casting can significantly enhance design flexibility and is often used in conjunction with other sand casting processes.

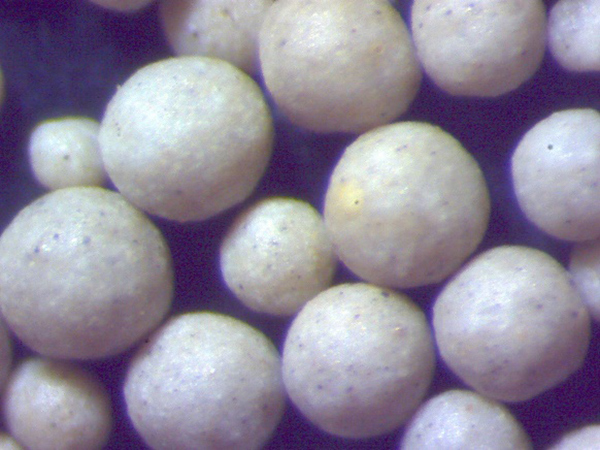

5. Chemical Bonded Sand Casting

In chemical bonded sand casting, chemical binders are used to hold the sand particles together instead of traditional clay. This results in molds with superior strength and stability. The process allows for the creation of intricate shapes with excellent surface finish. Although it can be more expensive due to the additional materials used, the advantages in terms of mold longevity and surface quality make it an attractive option for specialized applications.

Conclusion

Sand casting is a fundamental manufacturing process that continues to play a pivotal role in various industries. Each type of sand casting method offers distinct benefits, making them suitable for different applications based on factors like production volume, part complexity, and material properties. As technology evolves, the sand casting process continues to adapt and innovate, ensuring its relevance in modern manufacturing. Whether through green sand, dry sand, skin-dried sand, core sand, or chemical bonded sand, the versatility of sand casting is integral to producing high-quality metal components that meet the demands of a rapidly changing technological landscape.

Post time:ડીસેમ્બર . 11, 2024 07:31

Next:resin coated sand manufacturers