Sanding a 3D Print A Comprehensive Guide to Achieving a Smooth Finish

3D printing has revolutionized the way we create objects, offering remarkable versatility and the ability to produce complex shapes with relative ease. However, while 3D printing can yield impressive results right out of the machine, achieving a professional-looking finish often requires post-processing techniques, with sanding being one of the most effective methods. In this article, we will delve into the importance of sanding 3D prints, the materials and tools needed, and a step-by-step guide to achieve a smooth finish.

Why Sanding is Essential

Sanding plays a crucial role in enhancing the surface quality of 3D prints. Even with high-resolution printers, the layers of filament used in additive manufacturing can often create visible ridges and imperfections. Sanding not only smooths these surfaces but also prepares the print for painting or other finishing techniques. This is especially important for models used in presentations, displays, or as prototypes, where aesthetics can significantly impact the perception of the product.

Materials and Tools Needed

Before you start sanding your 3D print, gather the following materials and tools

1. Sandpaper Use a range of sandpaper grits for the best results. Start with 80-120 grit for initial smoothing and gradually move to finer grits (220, 400, and even 600 or higher) for a polished finish. 2. Sanding Sponge or Block These tools can provide better control and even pressure across the surfaces you’re sanding.

3. Safety Gear Always wear a mask and goggles to protect against fine dust particles generated during the sanding process.

4. Water Wet sanding can help minimize dust and produce an even smoother finish.

5. Finishers Depending on your desired outcome, consider using fillers and paints to further refine the look of your print after sanding.

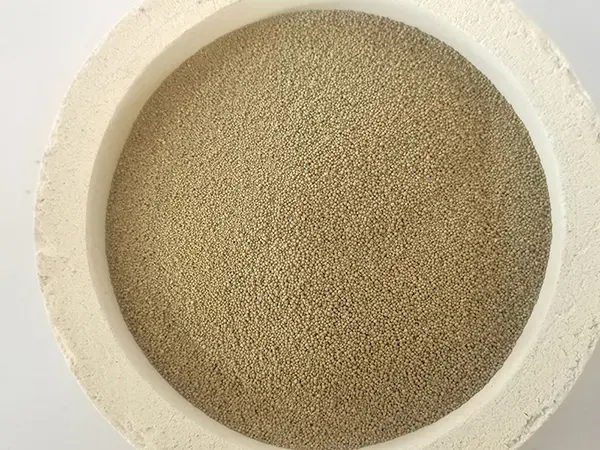

sanding a 3d print

Step-by-Step Sanding Process

1. Preparation Begin by cleaning your 3D print to remove any residual support material or grease. Inspect the model for any imperfections that might require extra attention.

2. Initial Sanding Start with coarse sandpaper (80-120 grit) to remove significant layer lines and rough patches. Sand in a circular motion to avoid creating flat spots, and check your progress frequently.

3. Progressing to Finer Grits After achieving a smoother surface with the coarse sandpaper, switch to finer grits, gradually working your way up. Each stage of sanding removes the scratches left by the previous grit.

4. Wet Sanding (Optional) For an ultra-smooth finish, consider wet sanding. Dampen the sandpaper with water to lubricate the surface. This technique helps to reduce dust and can minimize the risk of over-sanding.

5. Cleaning the Model After sanding, clean your model with a cloth or compressed air to remove dust particles. This step is crucial before applying any finishing coats.

6. Finishing Touches Depending on your intended use for the print, you may want to apply a filler or primer to fill in small holes and imperfections, followed by painting for a polished look.

Conclusion

Sanding your 3D prints is an essential step in the post-processing process that can dramatically enhance the quality and appearance of your models. With the right tools and techniques, even novice 3D printing enthusiasts can achieve professional-looking finishes. Whether you’re creating functional prototypes or artistic representations, investing time in the sanding process will pay off in the final product you showcase. So grab your sandpaper and start refining those prints today!

Post time:Dùbh . 18, 2024 22:23

Next:Top Suppliers for Sand Casting Services in Your Industry