Sand Casting An Overview of the Foundry Process

Sand casting, also known as sand mold casting, is one of the most widely used metal casting processes. It is a versatile and cost-effective method that allows for the production of complex shapes and sizes. This article explores the fundamentals of sand casting, its advantages, application areas, and the steps involved in the process.

What is Sand Casting?

Sand casting involves creating a mold from sand and using that mold to form metal parts. The process begins by creating a pattern that mirrors the desired final product. This pattern is typically made of metal, plastic, or wood. Once the pattern is ready, it is placed in a sand mixture that contains a binder, which holds the sand grains together. The mixture is packed around the pattern to form a mold.

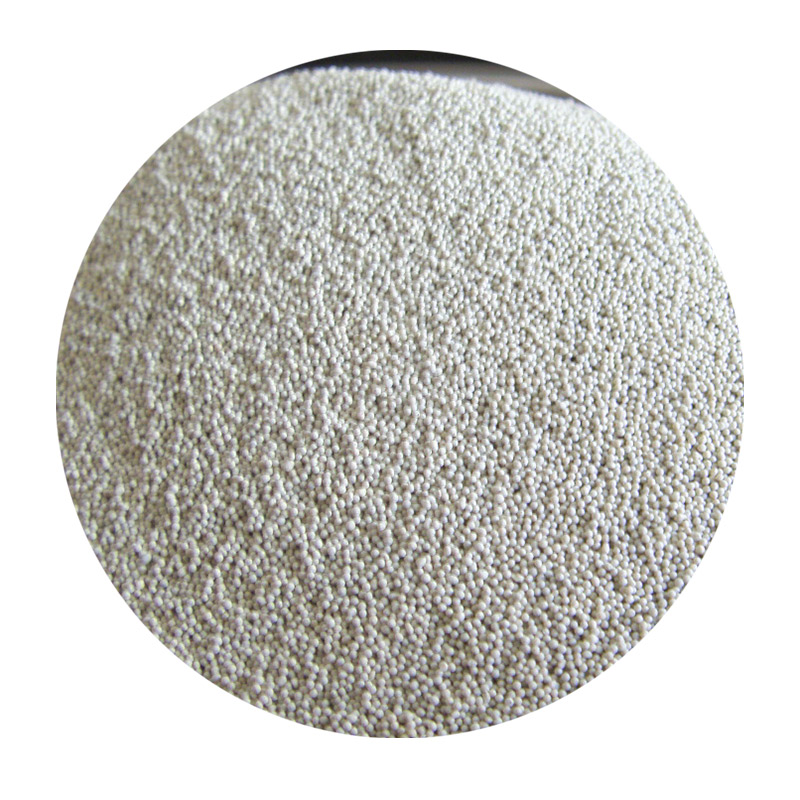

The key component of this process is the sand itself. High-quality silica sand is often used due to its excellent thermal properties and ability to create fine details in the mold. The sand mixture is then allowed to harden before being prepared for pouring the molten metal.

Steps in the Sand Casting Process

1. Pattern Creation The first step in sand casting is creating a pattern that represents the final product. Patterns can be made from different materials and often include allowances for shrinkage and machining.

2. Mold Preparation The pattern is pressed into the sand mixture to create a mold. This mold consists of two halves the cope (top half) and the drag (bottom half). The two halves are joined together for the pouring stage.

3. Core Making (if necessary) For parts requiring internal cavities, cores made of a sand mixture are created and placed within the mold.

4. Pouring Molten metal is poured into the mold cavity through a pouring cup, where it fills the space and takes the shape of the pattern. The metal must be heated to a temperature that allows it to flow easily.

5. Cooling After pouring, the metal is allowed to cool and solidify. Cooling times can vary depending on the size and type of metal being used.

6. Mold Removal Once the metal has cooled and solidified, the sand mold is carefully broken away to reveal the finished casting.

7. Finishing The casting often requires further processing, such as machining, grinding, or surface treatment, to achieve precise dimensions and a high-quality surface finish.

Advantages of Sand Casting

sand casting

Sand casting offers numerous advantages, making it a popular choice among manufacturers

- Cost-Effective The process requires relatively low initial investment and can be more economical for low to medium volumes compared to other casting processes.

- Versatility Sand casting can be used with a variety of metals, including aluminum, bronze, iron, and steel, making it suitable for a wide range of applications.

- Complex Shapes It allows for the production of complex geometries that might be difficult or impossible to achieve with other manufacturing processes.

- Large Parts Sand casting is capable of producing large parts that are often challenging to manufacture using other techniques.

Applications of Sand Casting

The applications of sand casting span various industries, including

- Automotive Components such as engine blocks, cylinder heads, and transmission cases are frequently produced using sand casting.

- Aerospace Parts that require high strength-to-weight ratios and complex geometries, like turbine housings and structural components, benefit from this process.

- Construction Sand casting is used to create large structural components and equipment used in heavy machinery and infrastructure projects.

- Art and Sculpture Artists and designers use sand casting to create intricate metal sculptures and decorative pieces.

Conclusion

In summary, sand casting is a foundational manufacturing process that remains relevant in modern industry. Its advantages in terms of cost, versatility, and complexity make it an attractive option for many applications. As technology advances and new materials are developed, sand casting will likely continue to evolve, maintaining its position as a key player in the manufacturing landscape. Whether for mass production or custom one-off pieces, the timeless method of sand casting showcases the interplay of art and engineering in metalworking.

Post time:Dùbh . 10, 2024 15:08

Next:use of foundry sand in concrete