The Significance of Large Sand Casting in Modern Manufacturing

Large sand casting is a crucial process in the foundry industry that is employed to manufacture a variety of metal components. This technique, which involves pouring molten metal into a sand mold, is particularly effective for producing large and complex shapes that are difficult to achieve through other manufacturing methods. The versatility, cost-effectiveness, and adaptability of large sand casting make it an invaluable technique in various sectors, including automotive, aerospace, and heavy machinery.

One of the primary advantages of large sand casting is its ability to produce intricate designs and large components in a single piece. The sand molds can be easily formed to accommodate complex geometries, which might be challenging to produce with traditional machining processes. This capability allows manufacturers to create parts such as engine blocks, pump housings, and turbine casings that are robust and meet the specific requirements of their applications.

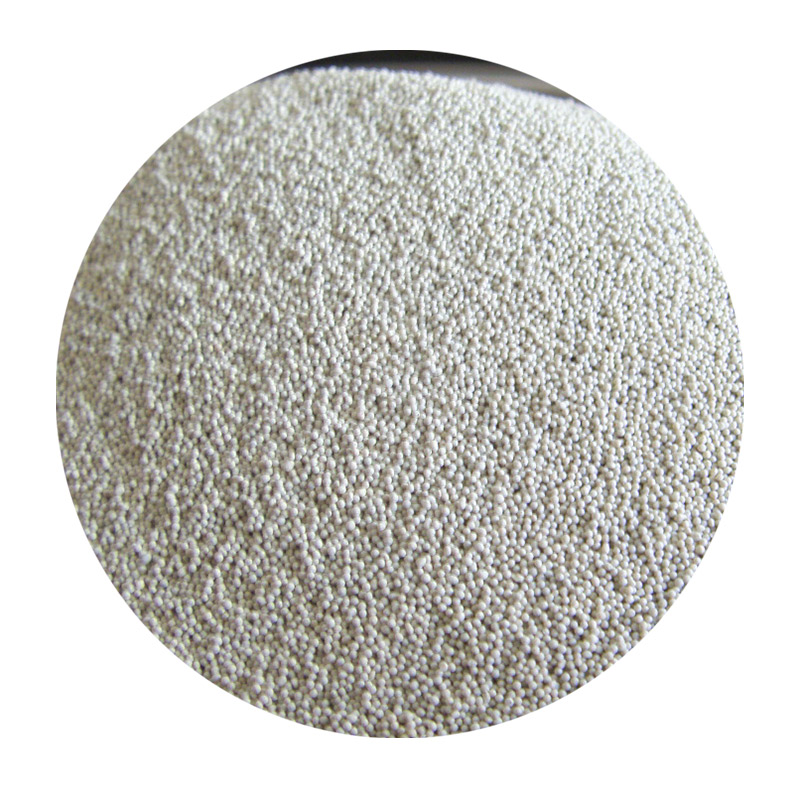

The materials used in large sand casting predominantly consist of silica sand, resin, and other additives, which combine to create a mold that is both durable and capable of withstanding high temperatures. The use of sand as the primary material also contributes to the flexibility of the casting process. For instance, when creating a mold, the sand can be modified in terms of grain size and composition to optimize the mold's properties for specific types of metals being cast. This adaptability is essential when working with various alloys, including aluminum, iron, and bronze, which have different melting points and flow characteristics.

large sand casting

In terms of cost, large sand casting offers significant benefits over other manufacturing methods, especially for low to medium production volumes. The molds can be reused multiple times, leading to lower overall production costs. Additionally, the straightforward design of sand molds means that the initial setup costs are relatively low compared to processes such as investment casting or die casting. For companies looking to produce large quantities of metal components without incurring excessive expenditures, large sand casting represents a favorable option.

However, the large sand casting process does come with its challenges. One of the primary concerns is the potential for defects in the final product. Porosity, surface imperfections, and dimensional inaccuracies can occur if the casting process is not meticulously controlled. Ensuring the quality of the sand, maintaining the proper molding techniques, and implementing rigorous quality control measures are essential steps in mitigating these risks. Advances in technology, such as computer-aided design (CAD) and computerized tomography (CT) for mold inspections, have significantly improved the precision and quality of large sand casting.

The environmental impact of large sand casting is also an important consideration. Traditional sand casting processes involve the use of silica sand, which raises concerns over resource depletion and environmental sustainability. However, many manufacturers are increasingly adopting green sand casting techniques, which utilize reclaimed sand and eco-friendly binders, reducing the carbon footprint and waste associated with the process.

In conclusion, large sand casting plays a pivotal role in modern manufacturing, providing the ability to create large, complex metal components efficiently and cost-effectively. Its adaptability, combined with advances in technology and a shift towards sustainable practices, positions large sand casting as a robust option for various industrial applications. As the demand for high-quality components continues to grow, the evolution of large sand casting methods will likely enhance its prominence in the manufacturing landscape, ensuring that it remains a critical manufacturing process for years to come.

Post time:Dùbh . 10, 2024 08:19

Next:Incorporating Sand into Resin for Enhanced Durability and Aesthetic Appeal