The Resin Sand Casting Process An Overview

Resin sand casting is an advanced manufacturing method that combines the traditional sand casting process with modern resin technology. This technique is particularly valued for its ability to produce high-precision and complex shapes that meet stringent quality standards. It is widely utilized in various industries, including automotive, aerospace, and machinery manufacturing, due to its versatility and efficiency.

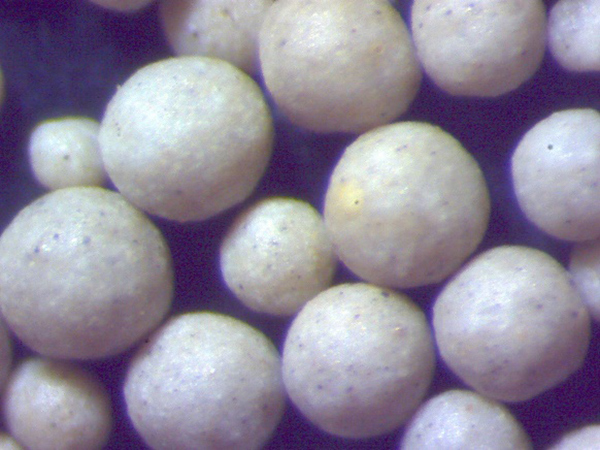

The process begins with the creation of a mold. In traditional sand casting, a mixture of sand and a binding agent is used to form the mold. However, in resin sand casting, the sand is mixed with a resin binder. This mixture is then heated to initiate a curing process, which solidifies the mold. The advantage of using resin lies in its ability to produce molds with finer details and better dimensional accuracy compared to conventional sand.

Once the mold is ready, molten metal is poured into the cavity. The resin-sand mold can withstand higher temperatures than standard sand molds, allowing for a wider range of metals to be cast, including alloys that may not be suitable for other processes. After the metal has cooled and solidified, the mold is broken away to reveal the final casting.

resin sand casting process

One of the significant benefits of resin sand casting is its ability to create highly intricate designs. The improved surface finish and tighter tolerances lead to reduced post-processing work. Additionally, the molds can be reused multiple times, maximizing productivity and minimizing waste.

However, there are some considerations when choosing resin sand casting. The initial setup costs can be higher due to the need for specialized materials and equipment. Moreover, the operational processes require careful control of temperature and timings to ensure quality and consistency in the casting.

In conclusion, the resin sand casting process is a sophisticated and efficient method for producing high-quality metal components. With its capacity for detailed designs and superior finishing, it is a preferred choice in industries that demand precision. As technology continues to advance, the applications and benefits of resin sand casting are likely to expand, making it an even more integral part of modern manufacturing practices.

Post time:Nov . 02, 2024 11:01

Next:super sand bond g2