An Overview of Foundry Sand Testing

The foundry industry plays a crucial role in producing metal castings for various applications, ranging from automotive to aerospace. An essential component of this process is foundry sand, which serves as a mold material in metal casting. The quality of foundry sand directly affects the quality of the final cast product. Therefore, the testing of foundry sand is an important procedure to ensure that the sand meets the required specifications for effective casting.

Importance of Foundry Sand

Foundry sand is a type of sand that is specifically formulated for casting processes. It is typically composed of silica grains, which provide the necessary properties for mold making. The characteristics of foundry sand, such as grain size, shape, and permeability, play a significant role in determining the overall quality of the cast product. Inadequate sand properties can lead to casting defects, which can be expensive to rectify and may result in compromised product performance.

Key Properties of Foundry Sand

The testing of foundry sand focuses on several key properties

1. Grain Size The size of the silica particles affects the mold's strength and surface finish. Testing involves using sieves to determine the distribution of grain sizes in the sand sample.

2. Permeability This property measures the sand's ability to allow gases to escape during the casting process. High permeability ensures that no gas pockets form in the mold, which can lead to defects. Permeability is typically assessed using standardized tests that measure the airflow through a sand sample.

3. Compacting Ability The ability of foundry sand to be compacted is critical for mold strength. Testing for compacting ability is often conducted using a standardized apparatus to determine how well the sand holds its shape under pressure.

4. Moisture Content The moisture level of the sand impacts its binding properties and the ease of mold formation. A moisture content tester is generally used to ensure that the moisture level is within the acceptable range for optimal performance.

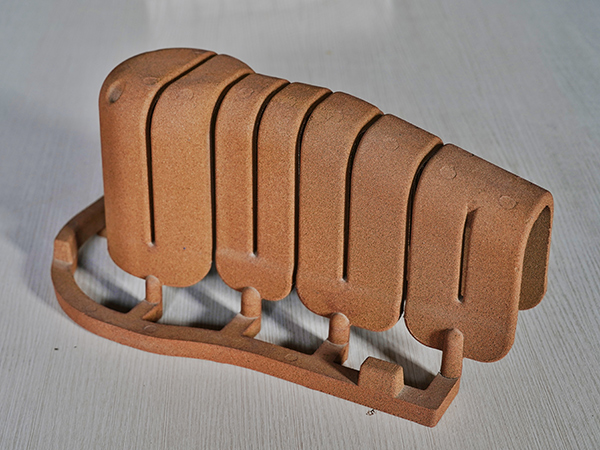

foundry sand testing

5. Strength The bonding strength of the sand mixture is also crucial. This property is tested using a universal testing machine to measure the sand's resistance to breakage when under load.

Testing Techniques

Various testing techniques are employed to ensure the quality of foundry sand. Common methods include

- Sieve Analysis This method involves passing sand through a series of sieves to determine the particle size distribution.

- Permeability Test The permeability of sand is assessed using a specific apparatus that measures the volume of air passing through the sand under specified conditions.

- Moisture Test This can involve using a moisture analyzer that measures the water content in the sand sample, ensuring it meets process requirements.

- Compressive Strength Testing This is performed on molded sand to measure how much force the mold can withstand before failing. The results provide insights into the mold's durability during the casting process.

Conclusion

Foundry sand testing is an essential element in the metal casting process, ensuring the quality and reliability of cast products. Through the evaluation of key properties like grain size, permeability, and strength, foundries can optimize their sand mixtures to reduce defects and enhance casting performance. As the foundry industry continues to evolve, the importance of stringent testing protocols for foundry sand cannot be overstated. With advancements in testing technology and techniques, foundries can maintain high standards of quality, ultimately leading to improved casting processes and superior final products. In an industry where precision and quality are paramount, understanding and implementing effective foundry sand testing practices is vital for success.

Post time:Déc . 31, 2024 15:14

Next:Innovative Techniques in Three-Dimensional Sand Printing for Creative Design Solutions