Understanding Sanding Resin A Comprehensive Guide

Sanding resin is an essential material used in various industries for achieving smooth finishes on different surfaces. It is particularly popular in woodworking, metalworking, and composite manufacturing. This article aims to explore what sanding resin is, its applications, advantages, types, and techniques for effective use.

What is Sanding Resin?

Sanding resin, often referred to as resin for sanding, is a synthetic compound typically derived from epoxies or polyurethanes. These substances are formulated to create a durable and smooth finish on surfaces when sanded. The resin acts as a bonding agent that fills gaps and imperfections in the material it is applied to. Upon curing, it becomes hard yet flexible, ensuring that surfaces are not only attractive but also more resistant to wear and weathering.

Applications of Sanding Resin

Sanding resin finds applications in various domains. In woodworking, it is often used to finish tabletops, cabinets, and intricate wood sculptures, providing an exceptional gloss and protecting the surface from moisture and damage. In metalworking, sanding resin helps achieve a mirrored finish on metal surfaces, enhancing aesthetics and durability.

In the automotive industry, sanding resin is crucial for ensuring the perfect paint job. It is used to prepare the surface before painting, ensuring that any blemishes are sanded down for a flawless finish. Additionally, in the field of composites, sanding resin is fundamental in the production of high-performance parts like those found in aerospace and marine applications.

Advantages of Sanding Resin

One of the primary advantages of sanding resin is its ability to create an extremely smooth surface. When properly sanded, surfaces treated with this resin can exhibit a glass-like finish. This is particularly beneficial for artists and craftsmen who require precision in their projects.

Moreover, sanding resin enhances the durability of the materials it coats. It provides additional resistance to scratches, UV rays, and moisture, making it an ideal choice for items exposed to the elements or heavy use.

Another significant benefit is its versatility. Sanding resin can be used on various substrates, including wood, metal, glass, and even plastics. This adaptability makes it a favored choice among manufacturers and craftsmen alike.

Types of Sanding Resin

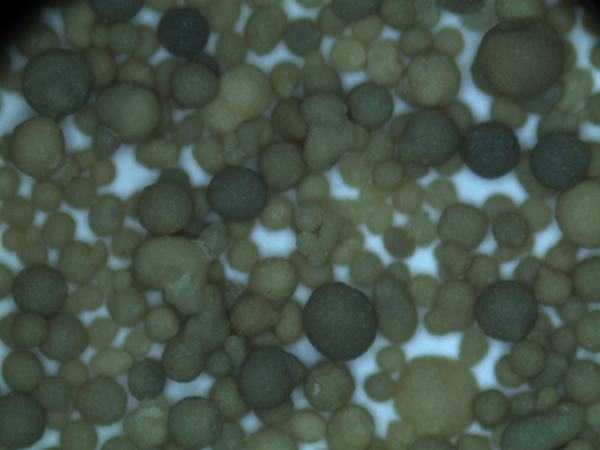

sanding resin

Sanding resins can be broadly categorized into two types epoxy resins and polyurethane resins. Epoxy resins are known for their superior bonding properties and chemical resistance, making them suitable for demanding applications. They cure to form a rigid, tough material ideal for structural applications.

Polyurethane resins, on the other hand, offer greater flexibility and a rich finish. They are often used in situations where a softer, more durable finish is required. Depending on the specific needs of the project, one type may be more advantageous than the other.

Techniques for Effective Use

To make the most of sanding resin, certain techniques should be followed

1. Surface Preparation Before applying resin, ensure that the surface is clean, dry, and free from contaminants. Any dirt or grease can affect adhesion and the final finish.

2. Application Apply the sanding resin using a brush, roller, or spray. Ensure an even coat is applied to avoid drips and uneven surfaces.

3. Curing Allow the resin to cure completely according to the manufacturer's instructions. This process is crucial for achieving the desired hardness and finish.

4. Sanding Once cured, use progressive grits of sandpaper—starting with a coarse grit and moving to finer grits—to achieve an ultra-smooth surface. Always sand in a consistent direction to avoid scratches.

5. Finishing After sanding, consider applying a final coat of a protective finish, such as varnish or sealant, to enhance the durability and appearance of the resin-coated surface.

Conclusion

Sanding resin is an invaluable material that serves myriad applications across different industries, from woodworking to automotive refinishing. Understanding its properties, advantages, and proper techniques can significantly enhance the quality of your projects. Whether you are a hobbyist or a professional, mastering the use of sanding resin can lead to stunning results and greater satisfaction in your craftsmanship.

Post time:joulu . 31, 2024 20:07

Next:Techniques for Casting Sand in Resin for Stunning Art Projects