Is Sand Casting Sustainable?

Sand casting is a traditional metal casting process that involves pouring molten metal into a mold made from sand. This method has been used for centuries and remains popular due to its versatility, cost-effectiveness, and ability to create complex shapes. However, in the contemporary context, sustainability has become a crucial aspect of manufacturing processes, prompting a reevaluation of techniques like sand casting. This article explores the sustainability of sand casting by considering its environmental impact, resource utilization, and potential for innovation and improvement.

Environmental Impact

One of the primary concerns regarding the sustainability of sand casting is its environmental footprint. The process itself is relatively energy-intensive, as it requires the melting of metal, which typically demands high temperatures. The energy consumption associated with this stage can lead to significant greenhouse gas emissions, particularly if the energy source is fossil fuels. However, many foundries are beginning to adopt renewable energy sources to mitigate this impact, reducing the overall carbon footprint of the sand casting process.

Another factor to consider is the waste generated during production. Sand casting produces waste sand, which is often disposed of in landfills. However, advancements in recycling techniques have emerged, allowing for the reuse of foundry sand in various applications, including construction and land reclamation. This practice not only minimizes waste but also reduces the demand for virgin materials, promoting a circular economy.

Resource Utilization

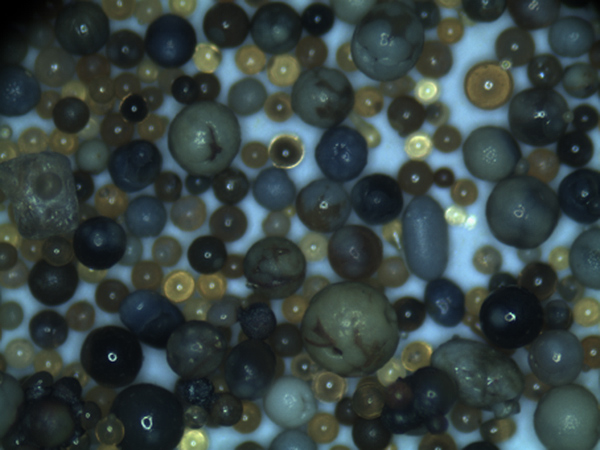

The materials used in sand casting also play a critical role in its sustainability. Sand, a primary component of the casting process, is plentiful and can be sourced sustainably. However, the extraction of silica sand can lead to environmental degradation if not done responsibly. Sustainable sourcing practices, such as ensuring minimal disruption to ecosystems and replenishing sand from responsible locations, are essential in maintaining the ecological balance.

is sand casting sustainable

Additionally, the metals used in sand casting can influence its sustainability. The industry is increasingly focusing on the use of recycled metals, which significantly reduces the environmental impact associated with mining and processing virgin materials. By utilizing scrap metal, foundries can lessen their ecological footprint while promoting resource conservation.

Technological Innovations

Technological advancements within the sand casting industry hold promise for enhancing sustainability. For instance, the adoption of computer-aided design (CAD) and simulation software allows engineers to design more efficient molds that minimize material waste. Furthermore, 3D printing technologies are being integrated into the sand casting process, enabling the production of molds with intricate designs that would otherwise require surplus material.

Moreover, innovations in binder materials have emerged, improving the strength of molds while minimizing the environmental impact. Traditional binders often contain harmful chemicals, but the development of eco-friendly alternatives, such as bio-based binders, can reduce air toxicity and promote a healthier working environment.

Conclusion

In conclusion, while sand casting has its challenges regarding sustainability, significant strides are being made to enhance the ecological soundness of this ancient manufacturing process. By focusing on reducing energy consumption, minimizing waste, responsibly sourcing materials, and leveraging technological innovations, the sand casting industry can become more sustainable.

The sustainability of sand casting is not just a matter of reducing its negative impacts; it also involves embracing opportunities for improvement and advancement. As industries continue to prioritize environmental consciousness, sand casting can adapt to meet these challenges, maintaining its relevance and utility in the modern manufacturing landscape. By investing in sustainable practices, the sand casting industry can play a crucial role in a more sustainable future, balancing production needs with environmental stewardship.

Post time:دسامبر . 24, 2024 20:44

Next:Innovative Techniques in 3D Sand Printing for Enhanced Manufacturing Efficiency