The Importance of Buying Sand Casting Services

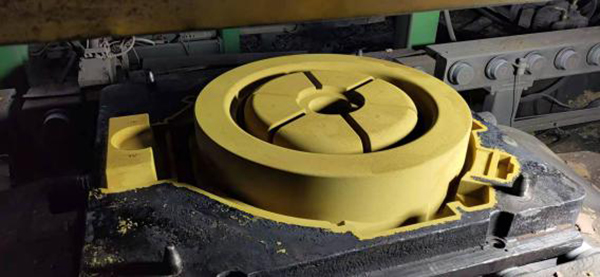

In the world of manufacturing, sand casting is one of the oldest and most versatile processes for producing metal parts and components. It involves creating a mold from a mixture of sand and a bonding agent, pouring molten metal into the mold, and allowing it to solidify. Once the metal has cooled and solidified, the mold is broken away to reveal the finished product. This method is invaluable across various industries, including automotive, aerospace, and art. When considering manufacturing options, the decision to buy sand casting services can offer numerous advantages that are worth exploring.

Cost-Effectiveness

One of the primary reasons manufacturers choose sand casting is its cost-effectiveness. The materials required for sand casting—primarily sand and binder—are relatively inexpensive compared to other casting methods. Furthermore, the molds can be produced in a short amount of time, reducing overall production costs significantly. For businesses looking to produce metal parts on a budget, buying sand casting services can provide high-quality results without compromising financial resources.

Versatility in Design

Sand casting is renowned for its versatility in design capabilities. It can accommodate a wide range of sizes and shapes, making it suitable for both large and small parts. This adaptability is particularly advantageous for industries that require custom solutions or those producing one-off prototypes. The ability to craft complex geometries, including intricate internal passages, allows engineers and designers greater freedom in their projects. For organizations looking to innovate and push the boundaries of their designs, collaborating with a sand casting service provider can unlock new possibilities.

Capability of Handling Various Materials

Another compelling reason to consider sand casting services is the variety of materials that can be used in the process. While commonly associated with ferrous metals like cast iron and steel, sand casting can also accommodate non-ferrous metals such as aluminum, bronze, and brass. This flexibility enables companies to select the most suitable material for their specific applications, whether they require lightweight components or corrosion-resistant parts. When you buy sand casting services, you gain access to a range of material options tailored to meet the demands of your project.

buy sand casting

Scalability

For businesses anticipating fluctuating demand or those that require both prototype development and mass production, sand casting offers superior scalability. Small batches can be produced economically, and as production needs grow, the process can be easily scaled up without significant investment in new equipment. This scalability is particularly useful for startups and small manufacturers that may experience erratic order volumes while establishing their market presence. Engaging a sand casting service allows these businesses to grow strategically and responsively.

Efficient Production Processes

Manufacturers looking to optimize their production processes often turn to sand casting due to its efficiency. The setup time for sand casting is generally shorter than for other methods, such as die casting or investment casting. Additionally, sand casting allows for rapid changes in design; if adjustments are needed, they can often be made quickly without extensive retooling. This agility in production is crucial in today’s fast-paced markets, where time-to-market can be a significant competitive advantage.

Quality Assurance

When selecting a sand casting service, quality assurance becomes paramount. Reputable sand casting companies often adhere to strict quality control measures, ensuring that the produced components meet industry standards and specifications. Investing in professional sand casting services can lead to improved product quality while minimizing defects and rework costs. Manufacturers can rest assured that their components will perform reliably in their intended applications, reducing the risk of costly failures down the line.

Conclusion

In conclusion, buying sand casting services offers an array of benefits that can significantly enhance manufacturing capabilities. With cost-effectiveness, versatile design options, material flexibility, scalability, efficient production processes, and quality assurance, businesses can leverage sand casting to meet their unique needs. As industries continue to evolve and seek innovative solutions, sand casting remains a cornerstone of modern manufacturing practices. For companies looking to streamline production processes and create high-quality metal components, investing in sand casting services is a strategic decision that can yield long-term advantages.

Post time:نوامبر . 20, 2024 04:17

Next:how sand casting is done