The Art of Sand Casting A Timeless Metalworking Technique

Sand casting is one of the oldest and most versatile metalworking processes still in use today. It involves creating a mold from a mixture of sand and a binding agent to produce metal parts. Due to its simplicity and cost-effectiveness, sand casting has been a preferred method in various industries, ranging from automotive to aerospace, and even artistic metal sculptures.

Understanding the Basics

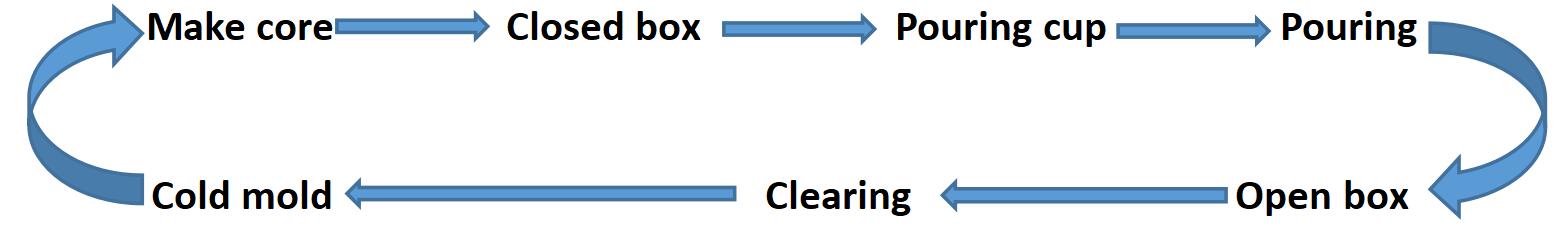

In sand casting, the process begins with the creation of a pattern—this is a replica of the desired object. The pattern is typically made from wood, metal, or plastic and can be a single piece or multiple parts, depending on the complexity of the object. Once the pattern is ready, it is pressed into a sand mixture, which is called molding sand. This mixture usually contains silica sand, clay, and water, creating a malleable yet sturdy mold.

The next step involves removing the pattern from the sand to create a cavity. After this, the mold is assembled and clamped together. Metal, usually in a molten state, is then poured into the cavity. The choice of metal can vary, including aluminum, iron, or bronze, dictated by the application and desired properties of the final product. Once the metal cools and solidifies, the mold is broken away, revealing the cast object.

Advantages of Sand Casting

youtube sand casting

Sand casting offers several significant benefits. One of its key advantages is its ability to create large parts that would be difficult or costly to manufacture with other methods. The flexibility in mold design allows for complex shapes and intricate details, making it suitable for both simple and elaborate designs.

Another important benefit is cost efficiency. The raw materials for sand casting are inexpensive and widely available. Moreover, the process does not require specialized machinery, making it accessible for small businesses and hobbyists. Additionally, because the sand can be reused multiple times, it minimizes waste and environmental impact.

Applications of Sand Casting

The applications of sand casting are diverse. In the automotive industry, for example, it is commonly used to produce engine blocks, cylinder heads, and other essential components. In aerospace, sand casting can create components that withstand high temperatures and stress. Artistic metalworkers also utilize sand casting to produce sculptures, jewelry, and custom pieces, showcasing the technique's versatility.

Conclusion

Sand casting remains an integral part of the metalworking landscape, standing the test of time due to its adaptability and efficiency. Whether you are interested in large-scale industrial applications or exploring artistic endeavors, mastering the art of sand casting can open up a world of possibilities. As technology continues to advance, integrating modern techniques with traditional sand casting can drive innovation, delivering enhanced precision and quality in metal casting. Thus, sand casting is not just a manufacturing process; it is a bridge connecting the past with the future of metalworking.

Post time:Urr . 07, 2024 04:50

Next:unique sand casting