The Importance of Steel Sand Casting Suppliers in Modern Manufacturing

Steel sand casting is a critical process in the manufacturing industry, providing a versatile and cost-effective method for producing a wide variety of components. The demand for high-quality castings has led to the emergence of numerous suppliers specializing in this method. Understanding the role and significance of these suppliers can shed light on the efficiency and quality assurance in the production processes.

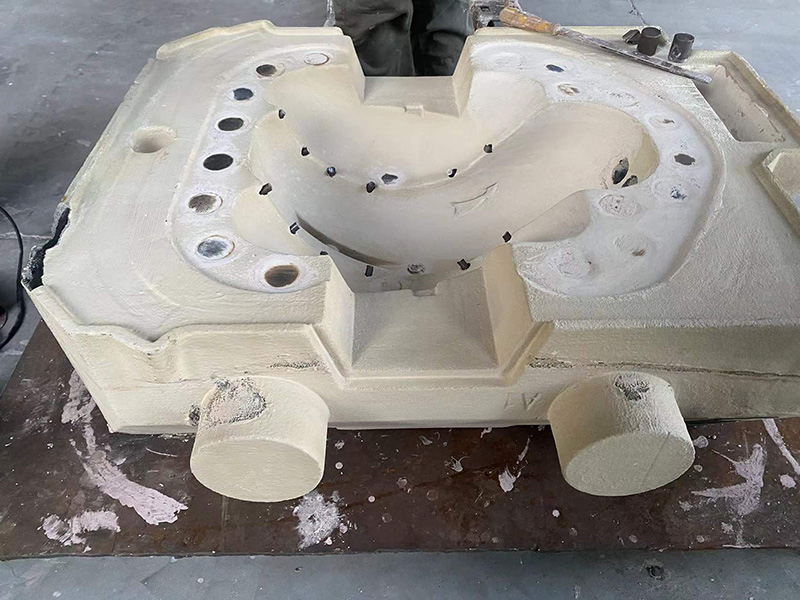

Steel sand casting involves pouring molten steel into a sand mold, where it cools and solidifies into a desired shape. This process is favored for its ability to produce complex geometries with excellent surface finishes and dimensional accuracy. However, the quality of the final product heavily relies on the expertise and capabilities of the casting suppliers involved.

One of the primary advantages of working with reputable steel sand casting suppliers is their ability to provide customized solutions. Different projects require specific materials, shapes, and production techniques, and established suppliers often have the flexibility to meet these diverse needs. This customization can involve modifications in design, material selection, and even the casting process itself, ensuring that the end product meets the specific requirements of the client.

In addition to customization, experienced suppliers are well-equipped with the latest technology and machinery, which enhances productivity and accuracy. Advanced technologies such as 3D printing for pattern making or automated sand molding systems can significantly improve the efficiency and quality of the casting process. Suppliers that invest in state-of-the-art equipment are often able to reduce lead times while maintaining stringent quality control.

steel sand casting suppliers

Quality assurance is another critical factor that distinguishes reliable steel sand casting suppliers from their competitors

. These suppliers typically adhere to strict industry standards and certifications, which guarantee that the castings produced meet rigorous performance and safety criteria. Implementing thorough testing and inspection protocols at various stages of production plays a vital role in preventing defects and ensuring consistent quality.Moreover, strong partnerships with suppliers can lead to enhanced collaboration and communication throughout the manufacturing process. Suppliers who maintain open lines of communication can provide valuable insights and recommendations that contribute to the overall success of a project. This collaboration often results in better design modifications, material selection, and improved production timelines.

Environmental considerations are also increasingly important in the selection of steel sand casting suppliers. Many companies today are looking for sustainable practices, such as recycling sand and reducing waste during the casting process. Suppliers committed to environmentally friendly practices not only help protect the planet but also enhance their appeal to businesses looking to improve their own sustainability efforts.

In conclusion, steel sand casting suppliers play a pivotal role in the manufacturing sector. Their ability to provide customized solutions, utilize advanced technology, maintain high-quality standards, and foster collaboration are essential for the successful production of cast components. As industries continue to evolve, the importance of choosing the right suppliers will only grow, shaping the future of manufacturing in a sustainable and innovative direction.

Post time:Ira . 25, 2024 20:26

Next:sand casting service