Sand Preparation in Foundry An Essential Process

Sand preparation is a critical aspect of the foundry industry, where metal casting processes are employed to create intricate components for various applications. The quality of the sand used in mold making significantly influences the final product, impacting both the casting quality and the overall efficiency of the manufacturing process. This article discusses the importance of sand preparation, its processes, and best practices.

Sand Preparation in Foundry An Essential Process

The sand preparation process typically involves several key steps selection, mixing, conditioning, and recycling. First, the right type of sand must be selected based on the casting requirements. For example, green sand, which is a mixture of sand, clay, and water, is commonly used due to its excellent moldability and mechanical properties.

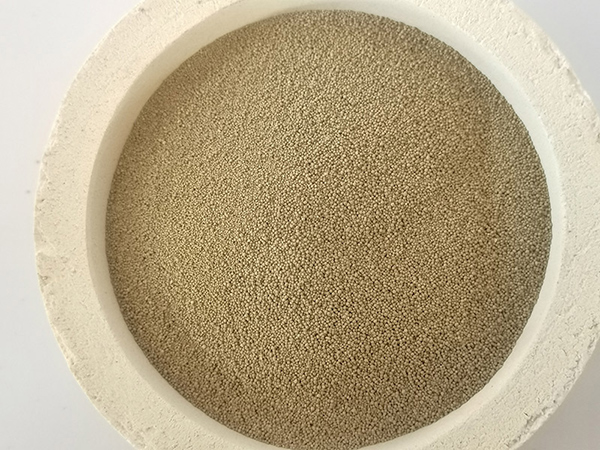

sand preparation in foundry

Once the sand is selected, the mixing process begins. This step is crucial as it ensures that the sand is uniformly blended with required additives, such as clay and moisture. The correct proportion of these materials is essential for achieving the desired properties. Inadequate mixing can lead to defects in the molds and, consequently, in the castings, such as poor surface finish or dimensional inaccuracies.

Conditioning is the next vital step in the sand preparation process. This involves controlling the moisture content and temperature of the sand mixture. Insufficient moisture can lead to dry sand that is too crumbly and cannot hold together, while excessive moisture can cause sticky sand that may not release easily from the molds. Therefore, achieving the right balance is paramount for producing strong and durable molds.

Recycling is another important aspect of sand preparation in foundries. Used sand can be reclaimed, treated, and reused, thereby reducing waste and minimizing the environmental impact of the foundry operations. Advanced technologies and methods are now available for recycling sand efficiently, making it a sustainable practice in modern foundries.

In conclusion, proper sand preparation is essential for successful metal casting in the foundry industry. By selecting the right type of sand, ensuring proper mixing and conditioning, and adopting effective recycling methods, foundries can enhance their productivity and the quality of their castings. As the industry continues to evolve, innovations in sand preparation will undoubtedly play a pivotal role in shaping the future of foundry practices.

Post time:Ira . 23, 2024 12:39

Next:3D Printing with Sand for Innovative Fill Solutions and Design Applications