Sand Casting Applications A Versatile Manufacturing Process

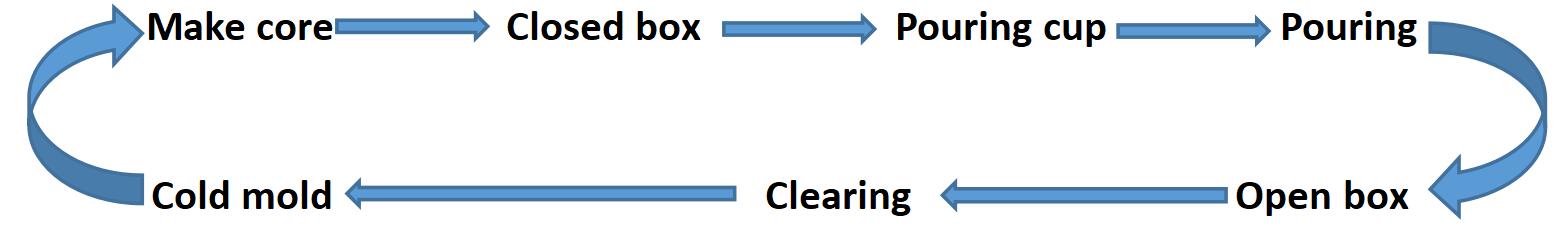

Sand casting, one of the oldest and most widely used metal casting processes, has found its application in diverse industries due to its simplicity, cost-effectiveness, and flexibility. The technique involves creating a mold from sand, which is then used to shape molten metal into various desired forms. This article explores the applications of sand casting across different sectors, showcasing its versatility and effectiveness.

One of the primary applications of sand casting is in the automotive industry. The production of engine blocks, cylinder heads, and other critical components often relies on sand casting due to its ability to produce complex shapes with a high degree of accuracy. The lightweight yet durable components created through this process contribute significantly to improving vehicle performance and fuel efficiency. Additionally, the automotive sector benefits from the rapid prototyping capabilities of sand casting, allowing manufacturers to test designs quickly and efficiently.

Sand Casting Applications A Versatile Manufacturing Process

The construction industry also utilizes sand casting for producing various tools and equipment. Elements such as brackets, frames, and scaffolding can easily be manufactured through sand casting, providing the necessary support and durability required in construction applications. The process also allows for customization of parts, catering to the specific needs of different construction projects.

sand casting applications

Another significant application of sand casting is in the production of art and decorative items. Sculptures, jewelry, and artistic components can be crafted with a high level of detail, allowing artists to bring their visions to life. The process allows for the replication of intricate designs and can accommodate unique artistic styles, making it a favored choice among sculptors and craftsmen.

In addition to these industries, sand casting is widely used in manufacturing various consumer goods and industrial components. From household appliances to machinery parts, the ability to cast large volumes of components with relative ease makes sand casting a preferred method in mass production settings.

Moreover, the continual improvement in sand casting techniques, including the introduction of computer-aided design (CAD) and simulation software, enhances the process's efficiency, precision, and overall quality. These advancements allow manufacturers to optimize designs, reduce material waste, and improve the cycle time of production.

In conclusion, sand casting remains a pivotal process in modern manufacturing, with applications ranging from automotive and aerospace to artistic endeavors and construction. Its adaptability and cost-effectiveness continue to make it a go-to choice for producing complex and high-quality components across various industries. As technology progresses, the future of sand casting looks promising, with even more innovative applications on the horizon.

Post time:Ira . 04, 2024 10:09

Next:dry sand casting process