The Manufacturing Process of Resin Coated Sand

Resin coated sand plays a crucial role in various industries, particularly in foundries where it is used for making molds and cores for metal casting. The process of manufacturing this specialized sand involves several intricate steps that ensure its quality and functionality. In this article, we will explore the comprehensive manufacturing process of resin coated sand, highlighting the key stages involved.

Raw Material Selection

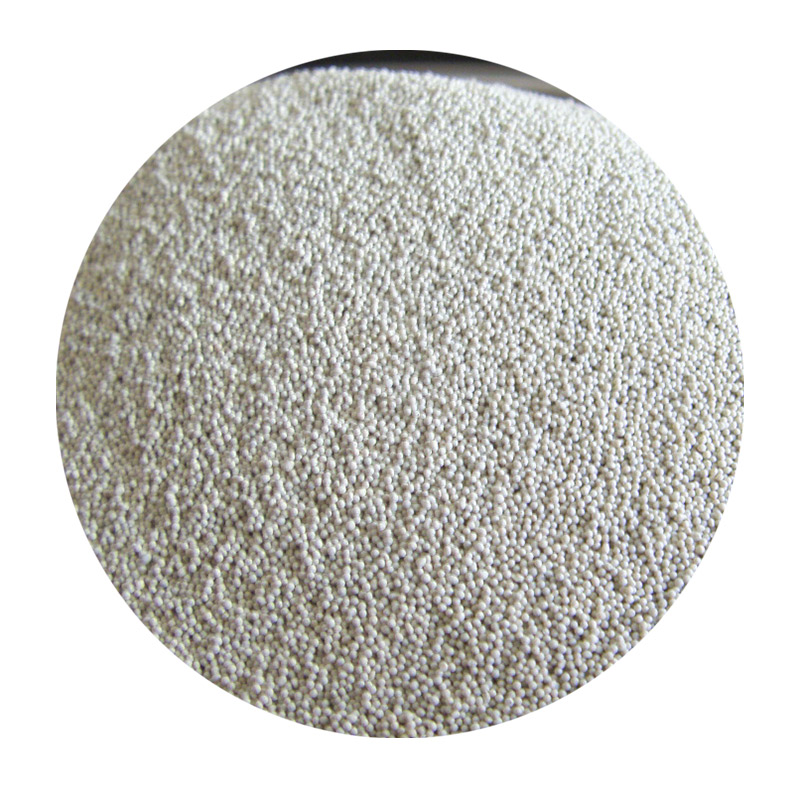

The first step in producing resin coated sand is the selection of high-quality raw materials. The primary component is silica sand, known for its excellent heat resistance and strength. Typically, the silica sand used has a consistent grain size and shape, which is essential for producing molds with precise dimensions. Additionally, the quality of the silica affects the final product's performance, making it imperative to choose the right type.

Sand Preparation

Once the silica sand is sourced, it undergoes a thorough preparation process. The sand is washed and dried to remove impurities and moisture that could hinder the coating process. This is accomplished using industrial washing systems, followed by drying in hot air ovens or fluidized bed dryers. The goal is to achieve a moisture content as low as possible, usually below 0.5%. Proper preparation ensures a uniform coating and improves the bond between the resin and sand particles.

Mixing with Resin

After the sand is prepared, it is mixed with a specially formulated resin. The most commonly used resins for this purpose are phenolic and furan resins due to their high thermal stability and excellent binding properties. The resins are often mixed with a hardener and sometimes additional additives to enhance performance characteristics, such as strength and workability.

The mixing process is typically carried out in large, rotating drums or batch mixers. The sand and resin mixture must be homogenous to ensure even coating. A critical aspect of this stage is controlling the temperature and humidity, as these factors can significantly influence the effectiveness of the resin bond.

Coating Application

resin coated sand manufacturing process

Once the sand has been mixed with the resin, the next step is the coating application. This is typically done using a multi-coater system where the sand passes through a series of spray nozzles. The coating process ensures that each grain of sand is evenly covered with resin. The application rate and the number of coating passes can be adjusted based on the desired properties of the final product.

In some cases, a curing agent may be added during the coating process to initiate the hardening of the resin

. The coated sand is then conveyed to a curing area where it undergoes a thermal curing process, allowing the resin to bond firmly with the sand grains.Curing Process

Curing is a vital part of the resin coated sand manufacturing process. During this phase, the coated sand is heated in curing ovens or through infrared heaters. This step not only helps in solidifying the resin but also enhances the mechanical properties of the sand. The curing temperature and duration depend on the type of resin used and the desired characteristics of the final product.

Quality Control

Quality control is integral throughout the manufacturing process. Samples of the resin coated sand are continuously tested for properties such as grain size, strength, and thermal stability. These tests ensure that the final product meets industry standards and specifications. Additionally, visual inspections are carried out to check for uniformity in coating and the absence of any defects.

Packaging and Distribution

Finally, once quality control checks are complete, the resin coated sand is packaged for distribution. It is typically stored in bags or bulk containers, ensuring that it remains dry and uncontaminated. The product is then shipped to foundries and other manufacturers who rely on high-quality resin coated sand for their casting needs.

Conclusion

The manufacturing process of resin coated sand is a complex and detailed procedure that requires precision and quality control at every stage. From selecting the right raw materials to the final packaging, each step plays a significant role in ensuring that the final product meets the expectations of the foundry industry. Understanding this process is essential for those involved in metal casting and highlights the importance of innovation in material manufacturing.

Post time:Aza . 20, 2024 20:31

Next:sand casting cast iron