The Importance of Quality Casting Sand for Sale in the Foundry Industry

Casting sand plays a crucial role in the foundry industry, serving as a primary material in the metal casting process. The effectiveness of casting, the quality of the finished product, and the efficiency of production largely depend on the type and quality of sand used. As such, the demand for high-quality casting sand for sale has been on the rise, making it a significant focus for manufacturers and suppliers alike.

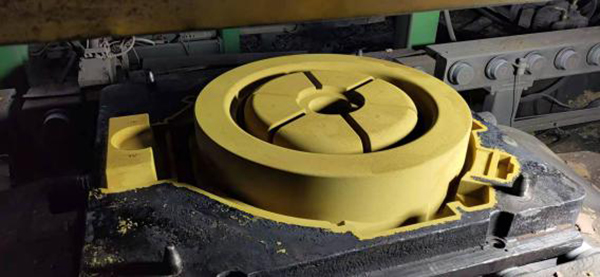

Casting sand is primarily composed of silica, but various additives can modify its properties to improve its performance. Common types of casting sands include green sand, silica sand, and resin-coated sand, each offering unique benefits for different casting applications. Green sand, for example, is a mixture of silica sand, clay, and moisture, making it versatile and economical. It is favored for its ability to produce intricate details, as it retains moisture well, allowing for fine features in casting molds.

In contrast, resin-coated sand provides a more durable solution, as the resin binds the sand particles together. This type of sand is particularly useful for high-temperature applications, such as casting ferrous and non-ferrous metals. Foundries that opt for resin-coated sand often experience reduced defects, leading to fewer rework costs and higher yields. As a result, this type of sand has gained popularity among foundries looking to enhance their production processes and the quality of their end products.

casting sand for sale

The rise in demand for casting sand highlights the importance of sourcing materials from reputable suppliers. Quality control is essential in the production of casting sand, as impurities can negatively affect the casting process. Suppliers must ensure that their sand is screened for contaminants and graded according to size to meet industry standards. The availability of casting sand for sale from reliable sources helps foundries maintain consistency in their operations and ultimately impacts the quality of the finished metal products.

Moreover, environmental considerations are increasingly influencing the choice of casting sand. Traditional mining practices for silica sand can lead to habitat destruction and other ecological concerns. This has propelled the foundry industry towards alternative materials and sustainable practices. Suppliers of casting sand are now exploring options such as recycled sand, which can significantly reduce the environmental footprint of metal casting operations. By promoting the use of eco-friendly sand, foundries can align themselves with global sustainability goals, appealing to environmentally-conscious consumers.

Furthermore, technological advancements in the production of casting sand are shaping the future of the industry. Innovations such as 3D printing have opened new avenues for mold production, and these methods require specific types of sand with precise characteristics. As 3D printing continues to gain traction, the demand for casting sand that meets these new requirements will grow. Suppliers must remain agile and responsive to the latest trends and advancements to stay competitive in this evolving market.

In conclusion, the significance of quality casting sand for sale in the foundry industry cannot be overstated. Its role in the metal casting process is pivotal, affecting everything from production efficiency to the final product's quality. Foundries must prioritize sourcing quality sand that meets their specific needs while considering environmental implications and technological developments. By doing so, they not only enhance their production capabilities but also contribute positively to the industry and the planet at large. As the demand for casting sand continues to evolve, the focus on quality, sustainability, and innovation will remain at the forefront of the foundry industry.

Post time:Aza . 06, 2024 23:47

Next:Het zandgietproces een overzicht van technieken en toepassingen in de industrie