The Innovation of 3D Printing with Sand A New Era in Manufacturing

In recent years, 3D printing has revolutionized various industries, from healthcare to aerospace. Among its many applications, 3D printing with sand has emerged as a groundbreaking technology that offers unique advantages for both prototyping and production. This innovative process not only enhances manufacturing efficiency but also opens new avenues for design and sustainability.

3D printing with sand primarily utilizes a technique known as binder jetting, where a liquid binding agent is selectively deposited onto layers of fine sand. This process creates a three-dimensional object by layering sand grains and binding them together until the desired form is achieved. One of the most significant benefits of using sand in 3D printing is the material's natural abundance and cost-effectiveness. Sand is plentiful and can be sourced from various locations, making it a viable option for large-scale manufacturing.

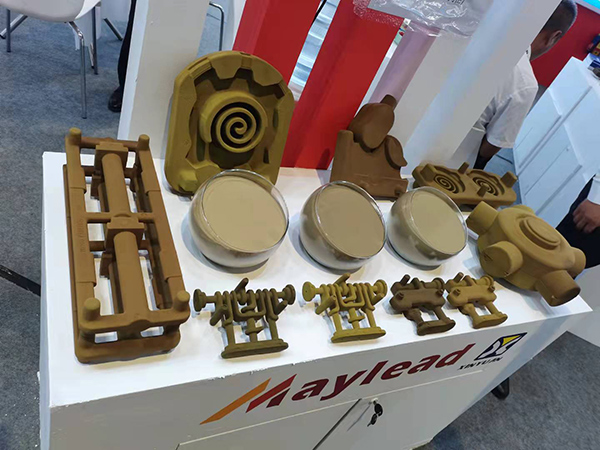

One of the most prominent applications of sand 3D printing is in the field of metal casting. Traditionally, creating sand molds for metal casting is a labor-intensive process that requires significant time and resources. However, by leveraging 3D printing technology, manufacturers can produce complex molds rapidly and with a high degree of accuracy. This not only accelerates the production timeline but also reduces waste, as the printer can create molds with intricate designs that would be challenging or impossible to achieve with conventional methods. Companies involved in sectors such as automotive and aerospace are already reaping the benefits of this technology, enabling them to streamline their operations and reduce costs significantly.

3d printer sand

Another noteworthy aspect of 3D sand printing is its sustainability potential. Conventional manufacturing processes often lead to considerable waste, both in terms of materials and energy. The additive nature of 3D printing allows for precise material usage, significantly minimizing waste. Furthermore, many 3D sand printing systems can utilize recycled materials, enhancing their environmentally friendly profile. This aligns with the growing emphasis on sustainable practices across industries, as businesses seek to reduce their carbon footprints and adhere to stricter environmental regulations.

Additionally, the flexibility of sand as a material opens up exciting possibilities for creativity in design. Designers and engineers can experiment with complex geometries that were previously unattainable in traditional processes. This freedom of design leads to the development of more efficient and lightweight components, enhancing performance while maintaining structural integrity. For industries such as healthcare, where custom-fit solutions are often required, this capability is invaluable. With 3D printing, it is easier than ever to create patient-specific anatomical models or prosthetics tailored to individual needs.

Looking ahead, the future of 3D printing with sand appears promising. As technology continues to advance, we can anticipate improvements in printing speeds, quality, and material properties. Research and development efforts are underway to explore new binding agents and sand compositions that could further enhance the capabilities of this innovative manufacturing method. The integration of artificial intelligence and machine learning into the design and production processes also holds the potential to optimize outcomes, making sand 3D printing even more efficient and reliable.

In conclusion, 3D printing with sand stands at the forefront of modern manufacturing, offering a multitude of advantages that can transform traditional practices. The blend of cost-effectiveness, sustainability, and creative freedom makes it an attractive option for various industries. As the technology matures, we can expect to see even wider adoption and more innovative applications, marking a new era in the way products are designed and manufactured. The possibilities are vast, and as we harness the power of sand through 3D printing, the future of manufacturing looks brighter than ever.

Post time:Abe . 31, 2024 04:39

Next:cast of sand castles 2014