The Evolution of 3D Printing in Sanding Machine Manufacturing

In the realm of manufacturing, the integration of 3D printing technologies has ushered in a transformative era, particularly in niche sectors like sanding machine production. As industries increasingly prioritize efficiency, precision, and customization, the synergy between traditional manufacturing methods and 3D printing allows for innovations that were previously unimaginable.

Understanding Sanding Machines

Sanding machines are essential tools in woodworking, metalworking, and various finishing processes. They are designed to smooth surfaces, prepare materials for paint or finish, and enhance aesthetic appeal. Traditional sanding machines vary from handheld models to large, industrial machines that can handle multiple workpieces simultaneously. However, the production of these machines often involves lengthy lead times, significant material waste, and limited design flexibility.

The Role of 3D Printing in Sanding Machine Design

3D printing, also known as additive manufacturing, offers a paradigm shift in how sanding machines can be designed and produced. This technology enables manufacturers to create complex geometries that traditional subtractive methods cannot achieve. For example, 3D-printed components can feature intricate airflow designs to improve dust extraction, enhancing the machine's overall efficiency.

Moreover, with 3D printing, manufacturers can utilize materials that are lighter and more durable, thereby improving the machine's performance without increasing its weight. Advanced polymers and composites can be used to create sanding machine parts that withstand wear and tear, extending their lifespan while maintaining optimal functionality.

Customization and Prototyping

One of the most compelling benefits of integrating 3D printing into the production of sanding machines is the capacity for rapid prototyping and customization. Engineers can quickly create prototypes of new sanding machine designs, test them in real-world applications, and iterate based on performance feedback. This drastically reduces the time between concept and production, allowing manufacturers to respond swiftly to market demands and technological advancements.

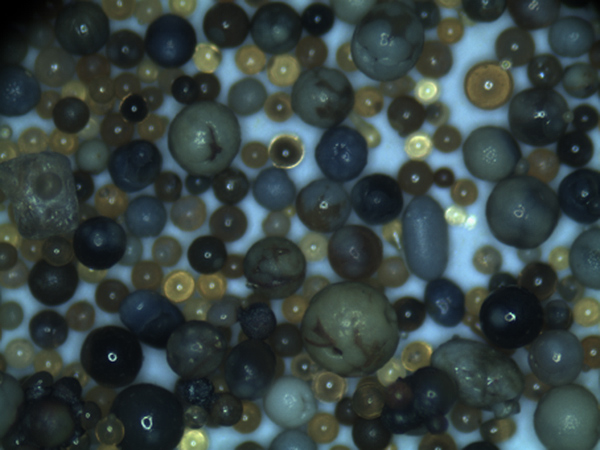

sanding machine 3d print

Furthermore, custom sanding machines tailored to specific client needs can be produced efficiently. Whether a small workshop needs a specialized belt sander or a large factory requires a high-throughput edge sander, 3D printing provides the flexibility to meet unique specifications without the heavy investments typically associated with custom tooling.

Environmental Considerations

The environmental impact of manufacturing processes is a significant concern for today’s industries. Traditional sanding machine production often involves extensive material waste and energy consumption. Conversely, 3D printing is an additive process, meaning material is added layer by layer only where needed. This reduces waste significantly, as leftover material can often be repurposed or recycled.

Additionally, the supply chain implications of 3D printing are notable. Localized production can minimize transportation emissions and logistics costs, leading to a reduction in the overall carbon footprint associated with manufacturing and distribution. As the world increasingly shifts towards sustainability, these attributes position 3D printing as a favorable alternative in the sanding machine sector.

Challenges and Future Directions

While the advantages of utilizing 3D printing in sanding machine manufacturing are compelling, challenges remain. The current limitations in printing speeds, material properties, and finish quality need to be addressed for wider adoption. Furthermore, businesses must adapt to new manufacturing paradigms, which may require re-skilling workers and re-evaluating quality assurance processes.

Looking to the future, the ongoing development of 3D printing technology promises to enhance its compatibility with industrial applications. The emergence of multi-material printing, more sophisticated sensors, and smart technologies may pave the way for the next generation of sanding machines—machines that not only perform tasks but also optimize their outputs through intelligent feedback systems.

Conclusion

The intersection of 3D printing and sanding machine manufacturing represents a forward-thinking approach to industry challenges. By harnessing the capabilities of additive manufacturing, businesses can innovate designs, reduce waste, and tailor machines to meet specific needs. As this technology continues to evolve, it is likely that 3D printing will play an increasingly integral role in enhancing the capabilities and efficiency of sanding machines, ultimately benefiting manufacturers and end-users alike.

Post time:dets. . 02, 2024 00:58

Next:Sandgussverfahren in der Fertigungstechnologie Ein Überblick über den Prozess