Understanding Fine Casting Sand The Foundation of Precision Casting

Casting is a critical process in manufacturing, where molten metal is poured into molds to produce intricate shapes and components. One of the most vital elements of this process is the material used for creating these molds, notably fine casting sand. This article delves into the significance, properties, and applications of fine casting sand in the foundry industry.

What is Fine Casting Sand?

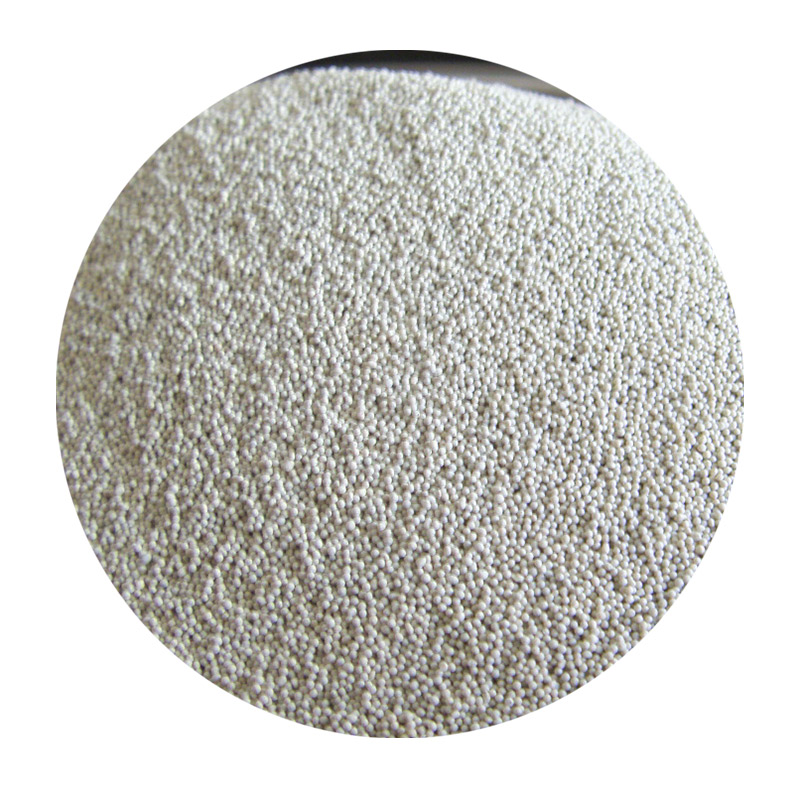

Fine casting sand, often referred to as silica sand, is a key ingredient in the sand mold casting process. Its primary purpose is to create molds that can withstand high temperatures and provide precise details of the intended shapes. Characterized by its fine particle size, fine casting sand ensures excellent mold surface finish and dimensional accuracy, making it ideal for producing complex designs and intricate components.

Properties of Fine Casting Sand

The quality of fine casting sand greatly influences the casting process and the final product. Several properties are crucial for effective casting

1. Particle Size and Distribution Fine casting sand typically has grain sizes ranging from 0.1 to 0.4 mm. A well-graded distribution helps in achieving a densified mold, which can hold up against the forces exerted during pouring and solidification of the metal.

2. Shape The shape of the sand grains can affect the mold’s strength and permeability. Angular grains provide better packing and support but may decrease the permeability required for gas escape during pouring.

3. Refractoriness Fine casting sand must withstand high temperatures without deforming or losing structural integrity. High refractoriness ensures that the sand mold does not break down when in contact with molten metal.

4. Bonding Properties While sand itself does not bind, additives such as clay can enhance its adhesive properties. This mix improves the strength of the mold and the quality of the final casting.

5. Permeability For successful sand casting, the mold should allow gases generated during metal pouring to escape. Fine casting sand, when mixed correctly, maintains adequate permeability to prevent defects like blowholes in the final products.

fine casting sand

Applications of Fine Casting Sand

Fine casting sand finds extensive use in various industries, particularly in metal casting foundries. Its applications include

- Automotive Industry The automotive industry heavily relies on casting processes for manufacturing engine blocks, cylinder heads, and other essential components. Fine casting sand enables the production of durable parts with complex geometries.

- Aerospace The precision required in aerospace components makes fine casting sand an ideal choice for producing lightweight yet strong parts, such as turbine blades and structural components.

- Artisan and Decorative Casting Beyond industry applications, fine casting sand is also used in art foundries for decorative items, sculptures, and custom designs. The detail captured in the molds allows for artistry in metalwork.

Challenges and Considerations

Despite its advantages, working with fine casting sand also presents challenges. For instance, refractoriness can vary between sand types, necessitating careful selection depending on the metal being cast. Additionally, issues like sand consolidation and the management of sand properties over multiple uses are crucial for efficient operations.

Environmental considerations also come into play, as silica dust can pose health hazards. Foundries must adopt proper safety protocols and consider alternatives to traditional fine casting sands, such as synthetic or reclaimed sands, to mitigate these risks.

Conclusion

Fine casting sand is undeniably a cornerstone of the sand casting process, enabling industries to produce precise, high-quality metal components. With its unique properties and applications, it facilitates the creation of everything from automotive parts to artistic sculptures. As technology advances, the demand for quality casting solutions will continue to rise, underlining the importance of fine casting sand in the manufacturing landscape. By addressing challenges and embracing innovative practices, the foundry industry can ensure that fine casting sand remains a vital resource for years to come.

Post time:dets. . 12, 2024 09:29

Next:china sand casting