Foundry Sand Service A Crucial Element in Metal Casting

Foundry sand services play an integral role in the metal casting industry. This specialized service provides high-quality sand crucial for the casting process, which involves shaping molten metal into desired forms. The quality of foundry sand directly impacts the accuracy, surface finish, and overall effectiveness of the cast product. As industries evolve, the demand for efficient and reliable foundry sand services continues to grow, emphasizing the importance of this sector.

Understanding Foundry Sand

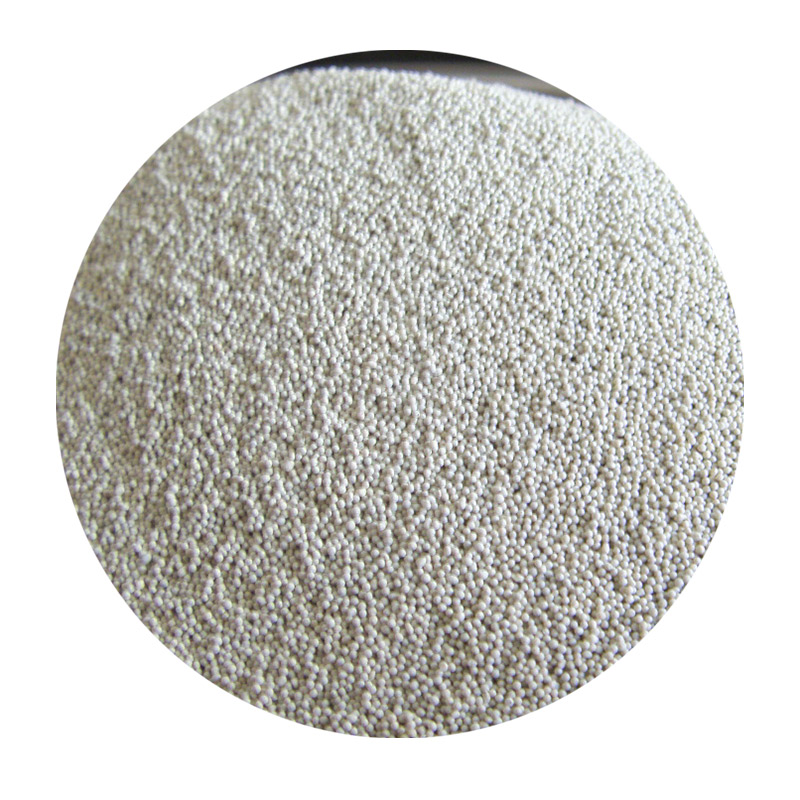

Foundry sand is a type of sand specifically used for metal casting. Silica sand is the most commonly used type, prized for its high melting point and thermal stability. The sand must be clean, free of impurities, and able to withstand the heat of molten metal without breaking down. It is often treated and processed to achieve the desired chemistry and physical properties. Various additives can be mixed with the sand to enhance its performance, such as clay, to improve bonding and thermal characteristics.

There are different types of foundry sand, including green sand, resin-coated sand, and investment casting sand, each with its own unique properties and applications. Green sand consists of silica sand mixed with clay and water, making it pliable and easy to shape. Resin-coated sand, on the other hand, is combined with a thermosetting resin that hardens when heated, providing excellent mold strength and surface finish.

The Role of Foundry Sand Services

Foundry sand services encompass a range of activities including sand classification, reclamation, and management. Providers of these services ensure a steady supply of high-quality sand tailored to the specific needs of foundries. They analyze the chemical and physical attributes of the sand, ensuring that it meets industry standards and customer requirements.

foundry sand service

One key aspect of foundry sand services is reclamation. During the casting process, sand can become contaminated with metal particles and other materials. Sand reclamation involves the recovery and purification of used sand to make it reusable. This process not only cuts costs for foundries but also aligns with sustainability goals by reducing waste. Advanced technologies, such as thermal and mechanical reclamation methods, are employed to restore sand to its original quality, allowing foundries to maintain production efficiency while minimizing environmental impact.

Industry Trends and Innovations

The foundry sand service sector is evolving, driven by advancements in technology and the need for sustainable practices. The adoption of digital technologies, including automation and data analytics, is transforming how sand services are delivered. Through the use of real-time monitoring systems, foundries can optimize their sand usage, reduce waste, and enhance overall productivity.

Moreover, there is a growing emphasis on sustainable materials in the foundry industry. Many companies are now exploring alternative materials or synthetic sands that can provide similar performance with a reduced environmental footprint. These innovative solutions are not only beneficial for the environment but also contribute to cost savings for foundries.

Conclusion

In conclusion, foundry sand services are paramount to the success and efficiency of the metal casting industry. By providing high-quality sand and innovative reclamation solutions, these services enhance the casting process while promoting sustainability. As the industry continues to advance, so too will the techniques and technologies behind foundry sand services, ensuring that they remain a vital component of metal casting for years to come. With a commitment to quality and innovation, foundry sand service providers will play a crucial role in shaping the future of manufacturing and casting, meeting the demands of an increasingly competitive marketplace.

Post time:Dic . 18, 2024 15:21

Next:what is a sand casting