How to Sand 3D Prints A Comprehensive Guide

3D printing has revolutionized the manufacturing and prototyping industries, offering incredible flexibility and creativity. However, one challenge that many users face is achieving a smooth finish on their prints. Sanding is one of the most effective methods to improve the surface quality of 3D prints. Whether you're preparing a model for painting or simply want to enhance its appearance, learning how to sand your 3D prints is essential. In this article, we will guide you through the steps to effectively sand your 3D printed objects.

Why Sand Your 3D Prints?

The underlying reason for sanding is to remove layer lines, the telltale sign of additive manufacturing. Layer lines can detract from the aesthetic appeal of the model, making it appear rough or unfinished. Sanding not only smooths these lines but also helps in preparing the surface for painting or further finishing processes like priming and polishing.

Materials Needed

Before you begin sanding, gather the necessary materials

1. Sandpaper Use a range of grits (from coarse to fine). A typical selection might include 80, 120, 220, and 400 grit paper. 2. Sanding Sponge These are useful for curved and complex surfaces. 3. Dust Mask Important for protecting your lungs from fine particles. 4. Safety Goggles To protect your eyes from dust. 5. Water For wet sanding, which can reduce dust and improve finish. 6. Rubbing Alcohol, or Acetone (for certain filament types like ABS) Can help in smoothing the surface with chemical sanding.

Steps to Sand Your 3D Prints

1. Preparation

Start by cleaning your 3D print to remove any residual dust, grease, or support material. Inspect the model for any imperfections that may need more attention before sanding. Secure the print in a stable position to prevent it from moving while you work.

2. Coarse Sanding

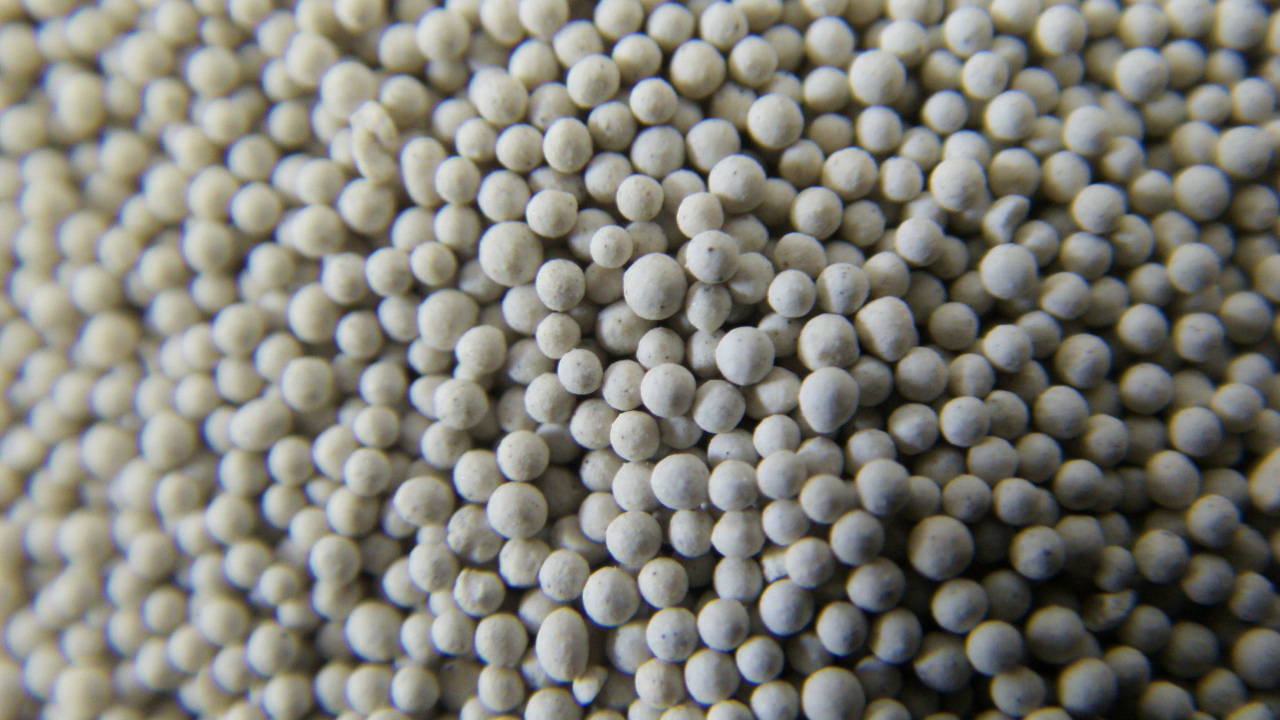

how to sand 3d prints

Begin with coarse sandpaper (80 grit). Sand the surface of the print, focusing on areas with noticeable layer lines. Use even, consistent strokes, and be mindful of pressure; too much can damage the print. Always sand with the grain of the surface, if applicable. For flat areas, use a flat surface as this will help in achieving an even finish.

3. Medium Sanding

Once you've removed the major imperfections with the coarse sandpaper, switch to medium grit (120-220). This will help to refine the surface further, smoothing out any rough patches left by the coarse sandpaper. Continue to sand evenly, and check your progress regularly to avoid oversanding.

4. Fine Sanding

For the final smoothing stage, use fine grit sandpaper (400 grit or higher). This step will prepare your print for any finishing methods you might apply later, such as painting or sealing. Take your time and ensure that the surface feels smooth to the touch.

5. Wet Sanding (Optional)

For an even smoother finish, consider wet sanding. This technique involves using water as a lubricant while sanding. It helps to reduce the production of dust and keeps the sandpaper from clogging. Dip the sandpaper in water or spray the surface, and follow the same sanding process.

6. Final Touches

Once you are satisfied with the smoothness, wash the print to remove any residues. You can use rubbing alcohol or soapy water for this process. Allow the print to dry completely before applying any paints or finishes.

Conclusion

Sanding your 3D prints is a crucial step in achieving professional-looking results. While it may seem tedious, with practice, you’ll develop a technique that works for you. Remember to take your time, be patient, and enjoy the rewarding process of transforming your prints into smooth, visually appealing pieces. Whether for a hobby or professional project, sanding can greatly enhance the quality of your 3D prints and elevate your skills as a designer or maker. So grab your sandpaper and get started on that perfect finish!

Post time:nov . 28, 2024 07:19

Next:Various Methods of Sand Casting and Their Unique Characteristics