The Sand-Resin Mixture A Comprehensive Overview

The incorporation of various materials into composites has revolutionized multiple industries, from construction to aerospace. One particularly intriguing combination is the sand-resin mixture, which has garnered attention for its diverse applications and unique properties. This article delves into the constituents, preparation methods, advantages, and applications of sand-resin mixtures.

The Sand-Resin Mixture A Comprehensive Overview

The preparation of a sand-resin mixture is a critical step that involves careful mixing and curing processes. Initially, the silica sand is thoroughly cleaned to remove impurities that could weaken the bond. Following this, the resin is mixed with a hardener according to the manufacturer's specifications. Once the two components are blended, the mixture is combined with the sand in measured proportions, typically ranging from 10% to 30% resin by weight. The mixture is then poured into molds where it is allowed to cure at room temperature or elevated conditions, depending on the specific requirements of the application.

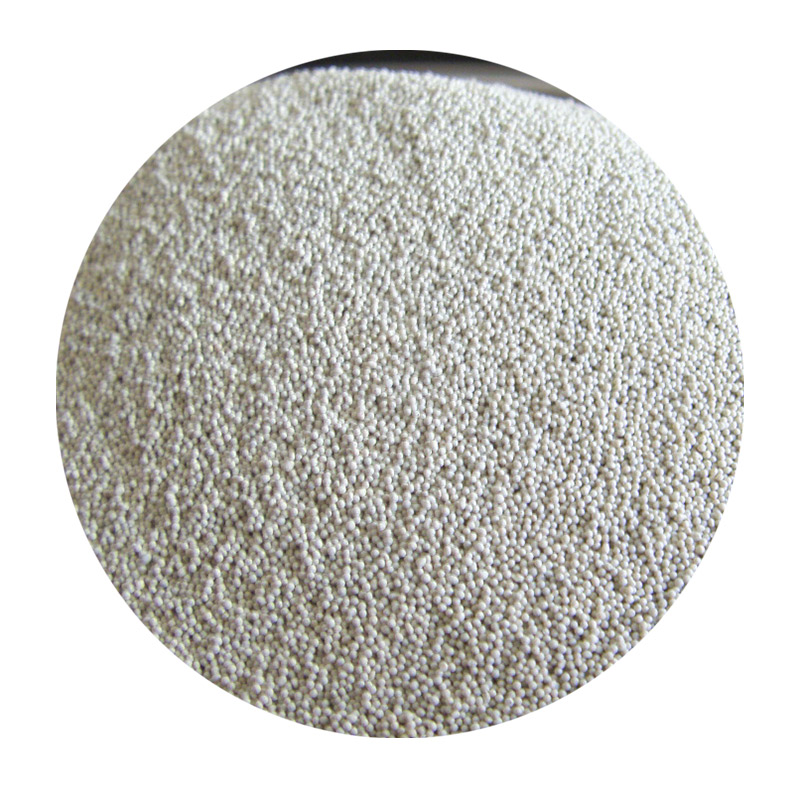

sand resin mixture

The advantages of using sand-resin mixtures are multifaceted. Firstly, they exhibit high compressive strength, making them ideal for applications that require structural support, such as in precast concrete and as infill materials. Additionally, these mixtures are resistant to water and chemicals, which extends their lifespan in harsh environments. Moreover, the lightweight nature of sand-resin composites, compared to traditional materials, provides a significant advantage in sectors like automotive and aerospace, where weight reduction is a crucial consideration.

In terms of applications, the sand-resin mixture has found a niche in various fields. In the construction industry, it is utilized for creating durable flooring, countertops, and decorative elements. Furthermore, manufacturers employ it in the production of molds and cores for casting processes, thanks to its high dimensional stability. The automotive sector benefits from this composite in the production of lightweight parts, while the art community utilizes sand-resin mixtures for crafting sculptures and decorative pieces.

In conclusion, the sand-resin mixture stands out as a versatile composite that brings together the strength of sand and the binding properties of resin. With continuous advancements in material science, the potential applications and improvements in formulations suggest that this mixture will remain a vital resource across multiple industries, paving the way for innovative solutions to modern challenges.

Post time:Σεπ . 22, 2024 10:38

Next:sand casting metal