Understanding Sand Casting Suppliers Your Guide to Quality Manufacturing

Sand casting, also known as sand mold casting, is a versatile and widely used method for producing metal parts and components. It involves creating a mold from sand and pouring molten metal into it to achieve the desired shape. The process is favored in various industries due to its ability to produce complex geometries, its cost-effectiveness for small to medium-sized production runs, and its flexibility with a variety of metals, including aluminum, iron, and bronze. However, the quality of the final product largely depends on the capabilities and reliability of sand casting suppliers.

The Role of Sand Casting Suppliers

Sand casting suppliers play a critical role in the manufacturing process. They provide the necessary materials, tools, and services required to produce high-quality castings. These suppliers can be categorized into several types, including foundries, raw material suppliers, and technology providers. Each of these suppliers contributes to different aspects of the casting process

1. Foundries These are the core providers of sand casting services. Foundries usually have the machinery and expertise needed to create mold patterns, pour metals, and perform post-casting operations like finishing and machining. When selecting a foundry, it’s essential to evaluate their production capabilities, technological advancements, and expertise with specific materials.

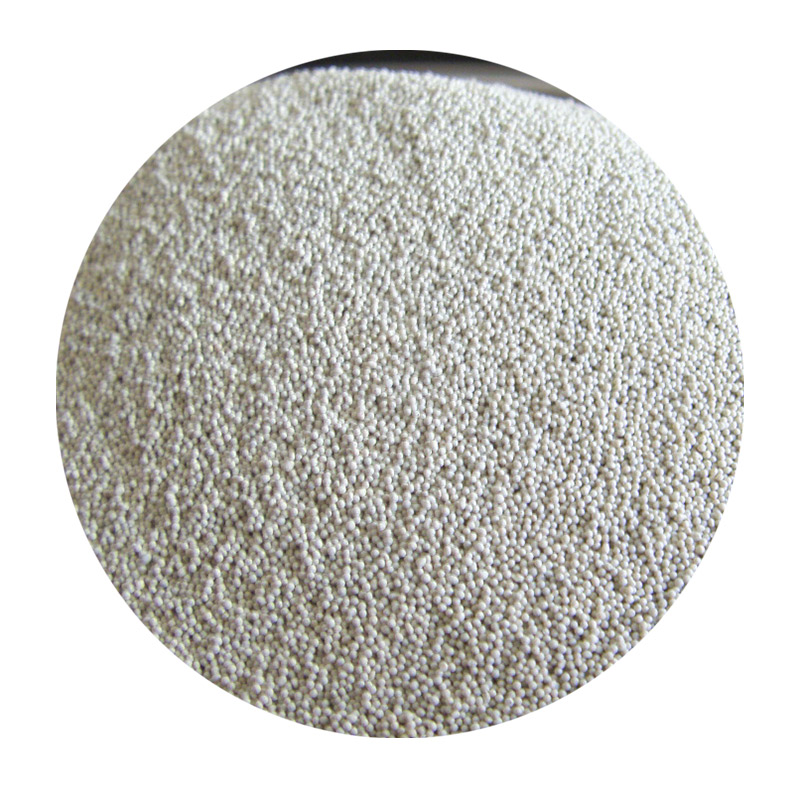

2. Raw Material Suppliers Quality sand and binding agents are crucial to the casting process. Suppliers of foundry sand (like silica sand) and binders (like resin) must meet stringent quality standards to ensure the production of sturdy and reliable molds. Additionally, the consistency of the sand is paramount, as any variation can lead to defects in the final casting.

3. Technology Providers Advances in technology, such as computer-aided design (CAD) and computer numerical control (CNC) machining, have significantly improved the effectiveness of sand casting. Suppliers who provide software and design tools can greatly enhance the precision of the casting process.

Choosing the Right Supplier

sand casting suppliers

Selecting the right sand casting supplier is critical for the success of your project. Here are some key factors to consider

1. Experience and Reputation Investigate the supplier’s track record within the industry. A supplier with a long-standing reputation for quality and reliability is often a safer choice. Look for reviews, testimonials, and case studies to gather insights into their previous work.

2. Capabilities and Services Assess the range of services the supplier offers. Do they provide designs and prototypes? Can they handle large-scale orders or specialized projects? A supplier that can adapt to your specific needs offers added value.

3. Quality Control Measures Quality assurance is a significant aspect of any manufacturing process. A good supplier should have stringent quality control measures in place, including regular testing and inspections of the raw materials and finished products.

4. Technical Support and Communication Open lines of communication are essential for a successful partnership. Choose a supplier that offers robust technical support and is responsive to your inquiries. This can help prevent misunderstandings and ensure that your requirements are met throughout the production process.

Conclusion

In conclusion, sand casting suppliers are instrumental in the production of high-quality metal components. Understanding the roles of different types of suppliers and carefully selecting one based on experience, capabilities, quality control, and communication can significantly enhance your manufacturing outcomes. Whether you are a small business or a large corporation, partnering with the right sand casting supplier can lead to superior products, efficient processes, and ultimately, greater customer satisfaction. With a growing emphasis on sustainability and innovation in the casting industry, the choice of supplier can also influence your company's commitment to environmentally friendly practices. As you navigate the complexities of sand casting, remember that a reliable supplier is not just a vendor but a strategic partner in your manufacturing journey.

Post time:Σεπ . 30, 2024 04:42

Next:Hiekka-valun perusteet ja sovellukset teollisuudessa