Sand Casting 101 An Introduction to the Art of Metal Casting

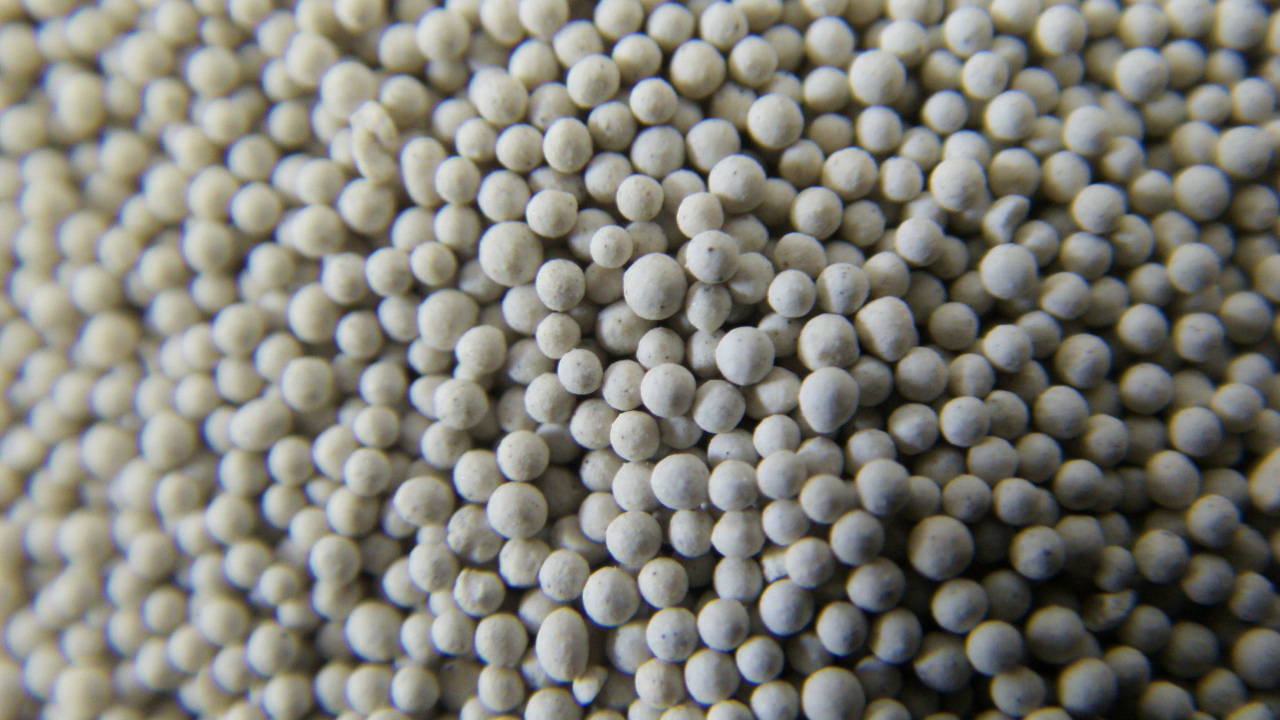

Sand casting is one of the oldest and most versatile methods for shaping metal into various forms and components. This process is widely utilized in industries ranging from automotive to aerospace and has remained relevant due to its simplicity, cost-effectiveness, and ability to produce complex shapes. In this article, we will explore the fundamentals of sand casting, including its process, materials, advantages, and applications.

Sand Casting 101 An Introduction to the Art of Metal Casting

Once the mold is prepared, the pattern is removed, leaving a cavity in the sand that is an exact replica of the desired component. This mold is then held together using a variety of methods, such as clamps or frames, to ensure it remains intact during the pouring process. The next step involves heating the metal until it reaches a molten state. This molten metal is subsequently poured into the mold cavity through a designated pouring basin, allowing it to fill every crevice and detail of the mold.

sand casting 101

After the metal has cooled and solidified, the mold is broken apart to reveal the cast metal object. Any surface imperfections or excess material, known as flash, can then be removed through processes like grinding or machining. The final product is often subjected to further treatments to enhance its mechanical properties or surface finish.

One of the key advantages of sand casting is its flexibility in producing diverse shapes and sizes. It can accommodate both large and small components, making it suitable for low-volume productions as well as large-scale manufacturing. Additionally, sand casting allows for the use of a variety of metal alloys, including aluminum, iron, bronze, and magnesium, making it applicable across numerous industries.

The cost-effectiveness of sand casting is another significant advantage, particularly in terms of tooling costs. Unlike more advanced methods such as injection molding, which requires expensive molds that can take months to create, sand casting molds are relatively inexpensive and can be produced quickly. This makes it a popular choice for prototyping and short-run productions.

In conclusion, sand casting remains a vital manufacturing process that promotes creativity and innovation in metalworking. Its unique combination of adaptability, cost-efficiency, and feasibility for complex designs ensures that it will continue to be a favored method for metal fabrication across various sectors. Whether you are designing a custom part or seeking to produce high-quality components, understanding the principles of sand casting can significantly enhance your manufacturing capabilities.

Post time:Σεπ . 02, 2024 15:55

Next:is sand casting sustainable