Lost Foam Casting An Overview of the Process and Advantages

Lost foam casting (LFC) is an innovative metal casting method that has gained popularity in various industrial applications due to its efficiency and ability to produce complex shapes with high precision. This technique involves the use of a foam pattern, typically made from polystyrene, which is coated with a ceramic shell. The process allows for the direct creation of intricate metal parts, making it a preferred choice in industries such as aerospace, automotive, and engineering.

Lost Foam Casting An Overview of the Process and Advantages

One of the significant advantages of lost foam casting is its ability to produce complex geometries that would be challenging or impossible to achieve with conventional casting methods. The foam patterns can be easily modified to accommodate changes in design, enabling rapid prototyping and reducing lead times in manufacturing. Moreover, LFC minimizes the need for machining post-casting, as the surface finish achieved during the process often meets the required tolerances.

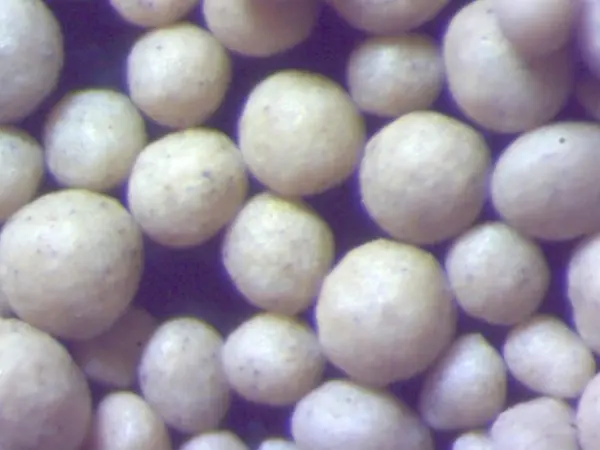

lost foam castings

Another benefit of lost foam casting is its material efficiency. The process produces less waste compared to traditional casting methods, where excess material may need to be trimmed away. This not only reduces costs but also aligns with sustainability efforts in manufacturing by lowering material consumption.

Furthermore, LFC is adaptable to various casting materials. It can be used with ferrous and non-ferrous metals, including aluminum, steel, and iron, allowing manufacturers to select the most suitable material for their specific application. This versatility makes LFC an attractive option for a wide range of industries, from creating engine components in automotive production to intricate parts in aerospace engineering.

In conclusion, lost foam casting is a cutting-edge method that offers significant advantages in terms of design flexibility, reduced material waste, and adaptability to multiple materials. As industries continue to pursue efficiency and innovation, LFC presents a compelling solution that meets the demands of modern manufacturing. Its ability to produce high-quality, complex parts while minimizing waste positions it as a leading choice for engineers and manufacturers looking to enhance their production capabilities. As technology evolves, the potential for lost foam casting will likely expand, opening new avenues for its application across various fields.

Post time:Σεπ . 08, 2024 14:20

Next:Golden Sands Development - Innovativa Fastighetslösningar