Understanding Foundry Sand Density

Foundry sand plays a crucial role in the metal casting industry, serving as a mold material for casting processes. The properties of foundry sand, including its density, significantly influence the overall quality of casted products. In this article, we will explore the concept of foundry sand density, its importance, the factors affecting it, and practical considerations for foundry operations.

What is Foundry Sand?

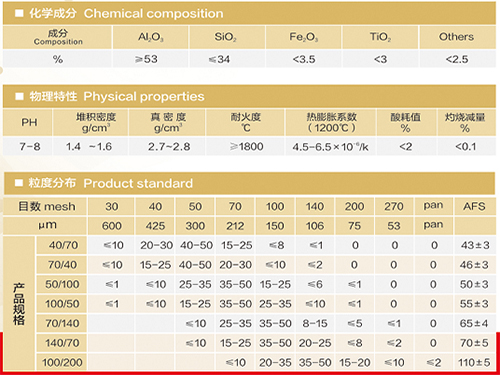

Foundry sand is a high-quality silica sand that is used in the manufacturing of metal castings. This sand is primarily composed of quartz and is characterized by its excellent flowability and thermal stability. Foundry sand is essential for creating the molds and cores that form the shapes of cast metal parts. The density of foundry sand refers to the mass of the sand per unit volume, typically measured in grams per cubic centimeter (g/cm³) or pounds per cubic foot (lb/ft³).

Importance of Foundry Sand Density

The density of foundry sand is a critical property that directly impacts the casting process and the quality of the final products. Here are some reasons why density matters

1. Mold Integrity A denser sand can improve the integrity of the mold, making it less likely to deform under pressure during casting. This integrity ensures that the final product has minimal defects.

2. Thermal Properties The density of the sand influences its thermal conductivity. A sand with higher density can better withstand the extreme temperatures of molten metal, helping to retain mold shape and prevent sand wash (eroded sand particles from the mold surface).

3. Flowability The density of foundry sand affects how well it flows into mold cavities. Proper flowability ensures that the mold is filled completely and evenly, leading to improved casting precision.

4. Weight Consideration The density of sand impacts the weight of sand molds, which is crucial for handling and transportation. Lighter molds may be easier to work with, but care must be taken not to compromise mold quality.

Factors Affecting Foundry Sand Density

Several factors can influence the density of foundry sand

foundry sand density

1. Grain Shape and Size The shape and size of the sand grains affect packing density. Angular grains pack more densely than rounded grains. Therefore, the grain characteristics should be carefully considered during sand selection.

2. Moisture Content The presence of moisture can affect the density of foundry sand. Excess moisture can lead to weight variations, impacting the consistency of the molds.

3. Additives Sometimes, additives are incorporated into foundry sand to improve performance. These additives can alter density and thermal properties, which can be beneficial or detrimental, depending on the application.

4. Compaction The manner in which the sand is compacted during the molding process also plays a significant role. More compaction generally increases density, leading to stronger molds.

Practical Considerations in Foundry Operations

For foundries, understanding and managing the density of sand is vital. Here are some strategies

1. Regular Testing Foundries should routinely test the density of their sand to ensure consistency. This testing can help identify variation in sand quality over time.

2. Use of Sand Reclamation Many foundries reclaim sand for reuse, but this can alter sand density. Reclaimed sand may need to be blended with fresh sand to maintain optimal density and performance.

3. Control of Moisture Content Careful monitoring of moisture levels during the sand storage and molding process is essential. Foundries should implement control measures to ensure the ideal moisture content for optimal density.

4. Invest in Technology Utilizing advanced technology for sand management can enhance the ability to monitor and control sand density effectively. Automated systems can ensure consistent mixing and compaction, promoting uniformity.

Conclusion

In conclusion, the density of foundry sand is a fundamental property that affects the efficiency and quality of the casting process. By understanding the factors that influence sand density and implementing effective management practices, foundries can enhance their production outcomes and maintain high standards of quality in their metal casting operations. As the industry continues to evolve, attention to such details will ensure that foundries remain competitive in an increasingly challenging market.

Post time:Okt . 16, 2024 10:04

Next:lost-foam casting