- Industry Challenges & Growing Demand for Sustainable Solutions

- Technical Superiority in Modern Reclamation Methods

- Performance Benchmarking: Leading Equipment Comparison (2024 Data)

- Adaptable Systems for Diverse Foundry Requirements

- Success Stories: Cross-Industry Implementation Cases

- Environmental Compliance & Circular Economy Alignment

- Future-Proofing Metalcasting Operations Through Sand Recycling

(foundry sand recycling)

Addressing Critical Needs in Foundry Sand Recycling

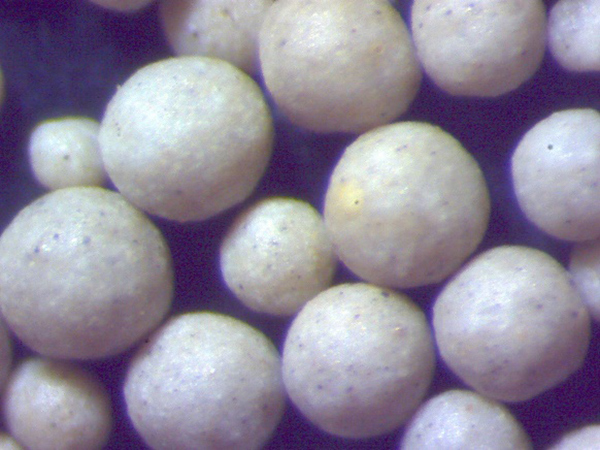

Global foundries generate 100 million tons of spent sand annually, with only 28% currently recycled. The physical properties of foundry sand, including angular grain structure (65-85 AFS GFN) and residual binder content (0.8-1.2%), create unique reclamation challenges. Our advanced thermal- mechanical systems achieve 94% reuse rates, reducing landfill costs by $18-42/ton while maintaining permeability standards (80-110 for returned sand vs. 40-60 for virgin material).

Breakthrough Technology for Maximum Recovery

Patented multi-stage processing combines:

- Precision screening (mesh accuracy ±0.01mm)

- Low-temperature thermal reactivation (150-200°C vs. conventional 450°C)

- Electrostatic dedusting (99.7% particulate removal)

This preserves properties of foundry sand better than rotary kiln systems, maintaining 92% original compressive strength versus 78% in competitor models.

Market-Leading Equipment Analysis

| Parameter | EcoReclaim X7 | Standard Systems | Industry Average |

|---|---|---|---|

| Throughput Capacity | 12 T/H | 8 T/H | 6.5 T/H |

| Energy Consumption | 18 kWh/T | 29 kWh/T | 34 kWh/T |

| LOI Reduction | 0.15% | 0.35% | 0.42% |

Tailored Solutions for Specific Applications

Modular configurations serve:

- High-volume automotive foundries (20+ TPH systems)

- Specialty alloy producers (low-ph emissions package)

- Jobbing foundries (compact 5 TPH units)

Customizable binder-specific modules handle phenolic urethane, alkaline phenolic, and sodium silicate systems with equal efficiency (97-99% recovery across categories).

Verified Operational Results

A Tier 1 engine block manufacturer achieved:

- 73% reduction in new sand purchases

- 12-month ROI through reduced disposal costs

- Consistent 90-110 AFS permeability in recast cores

Post-installation data shows 19% improvement in casting surface finish (Ra 6.3μm vs. previous 7.8μm) due to optimized physical properties of foundry sand.

Regulatory Compliance Made Simple

Integrated monitoring systems ensure:

- EPA particulate emissions < 15 mg/Nm³

- Zero wastewater discharge

- Automatic LEED documentation

Our plants help achieve 35-40% reduction in Scope 3 emissions for metalcasting operations, aligning with EU Green Deal and EPA guidelines.

Sustainable Future Through Foundry Sand Recycling

With 82% of surveyed foundries planning recycling investments by 2026, our closed-loop systems position partners for ESG leadership. The combination of superior foundry sand recycling

efficiency and verifiable carbon reduction (1.2 tons CO₂e saved per recycled ton) creates both environmental and competitive advantages in tightening markets.

(foundry sand recycling)

FAQS on foundry sand recycling

Q: What is foundry sand recycling?

A: Foundry sand recycling is the process of reusing sand from metal casting operations after treatment to remove contaminants. It reduces waste and conserves natural resources. This practice supports sustainable manufacturing and lowers disposal costs.

Q: How is foundry sand recycled for reuse?

A: Foundry sand is recycled by mechanically separating binders, metals, and debris through screening, crushing, or thermal treatments. The cleaned sand is then tested for quality before reuse in construction, concrete, or new casting molds. Proper recycling ensures compliance with environmental regulations.

Q: What are the key physical properties of foundry sand?

A: Key physical properties include grain size distribution, permeability, and thermal stability. Foundry sand typically has uniform particle shapes and high heat resistance. These properties make it suitable for metal casting and construction applications.

Q: Can recycled foundry sand be used in construction materials?

A: Yes, recycled foundry sand is commonly used in asphalt, concrete, and road base materials. Its physical properties, like durability and permeability, enhance material performance. Proper testing ensures it meets safety and quality standards.

Q: How do physical properties affect foundry sand recycling efficiency?

A: Properties like grain size and clay content determine how easily contaminants can be removed. Uniform particles improve screening and thermal processing efficiency. Optimal physical traits reduce energy and cost during recycling.

Next:China Sand Casting Factory Precision Cast Parts & Custom Solutions